Electric aircraft offer many advantages, but will they ever be able to compete on cost? As the world slowly recovers from COVID-19, the aviation sector is also expected to regain its former strength. Nevertheless, the pandemic has created a new focus on sustainability, and changes are expected in the post-COVID aviation fleet, such as fewer old-generation aircraft. The total aviation CO2 emissions calculated for each kilometre a passenger travels are not expected to change significantly soon, though, and total CO2 emissions may easily return to their 2019 levels.

Despite a renewed focus on sustainability in the light of the pandemic, the aviation industry remains at the very beginning of its energy transition. Currently, new technologies are receiving a great deal of attention, although they large-scale deployment is still several years away. Hydrogen propulsion and sustainable aviation fuel (SAF) are gaining traction, and both hybrid-electric and all-electric solutions are being actively developed. The dream of a ‘Tesla of the skies’ is real, offering a true zero-emission solution for air travel. Claims abound that electric aviation would be not just cleaner but also a cheaper way to travel. However, detractors often claim that electric would be more expensive than traditional forms of propulsion, creating a major stumbling block for the decarbonisation of the industry.

Royal NLR – Netherlands Aerospace Centre and Roland Berger decided to investigate this claim: is electric really more expensive?

And if the reverse turns out to be true and electric is actually cheaper, what impact could electric aircraft have on the aviation market?

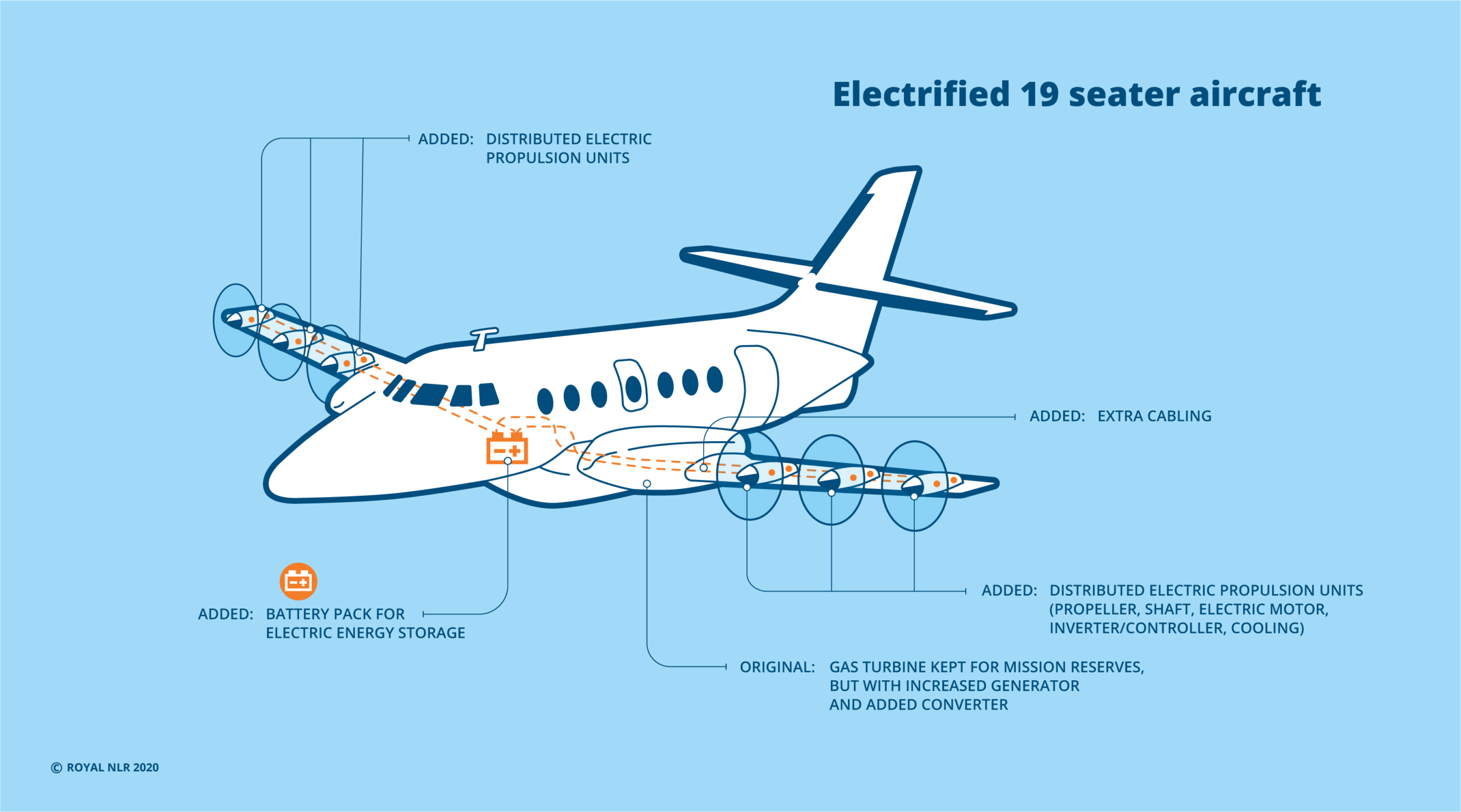

To get to the bottom of the question, the two parties developed the NLR-RB 19E, a hypothetical 19-seater sub-regional fully electric aircraft (as shown in the illustration). We arrived at this design by modifying a Jetstream 32, taking account of future aircraft and electric propulsion technologies, such as distributed propulsion. The NLR-RB 19E is dimensioned for a maximum range of 700 km. The question was what level of technology would in fact be needed to achieve an all-electric aircraft design for this range. As it turned out, we needed to make some highly speculative assumptions for electric technology, including a battery energy density of 1 kWh/kg. Even then, the original gas turbine would still be needed as a backup range extender for mission reserves: carrying additional batteries that are only used in exceptional circumstances is not very efficient.

Would it be competitive?

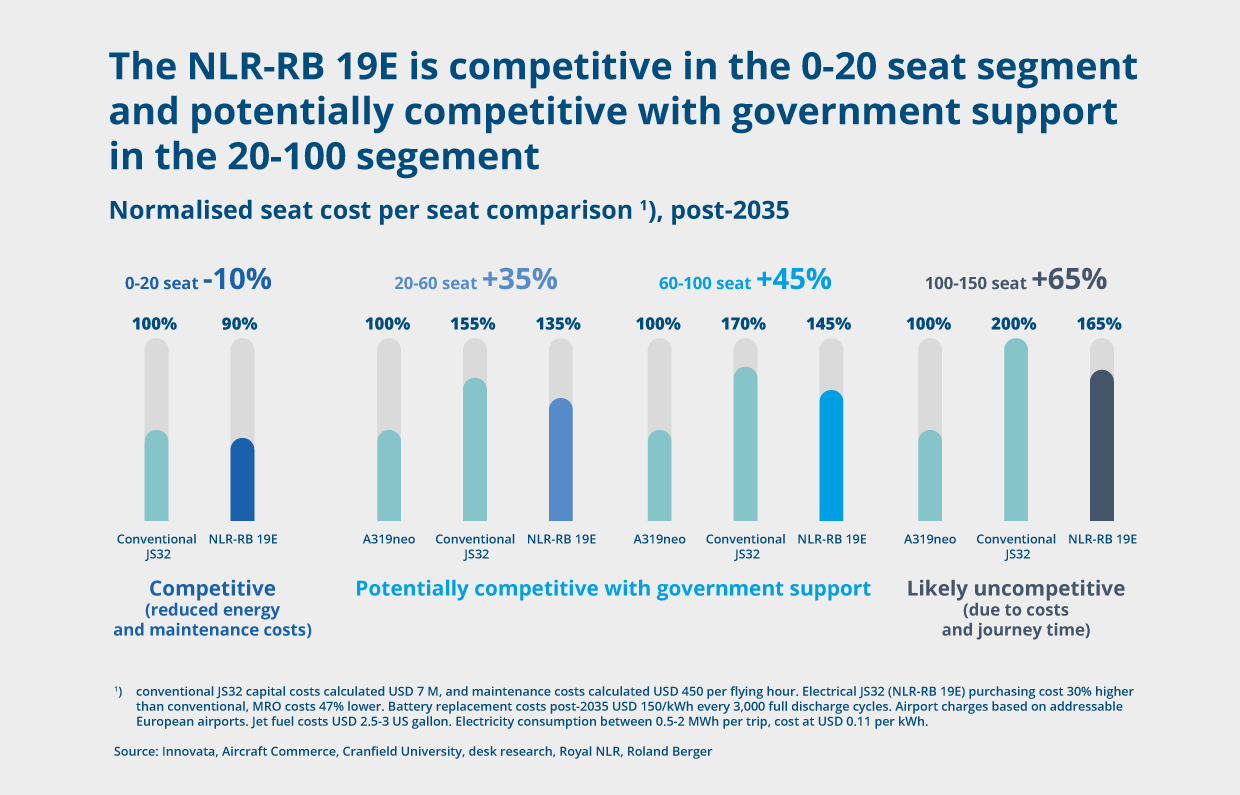

What are the commercial implications of our design? Comparing the aircraft like-for-like with conventional sub-regional aircraft, the electric NLR-RB 19E is 10 per cent less expensive on a per-seat basis. This advantage is driven largely by the electric aircraft’s lower maintenance and energy costs. However, compared to larger and more commonly flown aircraft, such as the 50-seater Embraer ERJ-145 or the French/Italian ATR 72 carrying up to 74 passengers, the electric NLR-RB 19E is more expensive on a per-seat basis – 35 per cent more expensive than the ERJ-145, as much as 45 per cent more expensive than the ATR 72, and 65 per cent more expensive than the Airbus A319neo (seating a maximum of 160 passengers). This additional cost is mainly driven by the higher proportion of airport charges in the case of the electric aircraft, a consequence of the need for more flights to be operated to carry the same number of passengers to the destination. So, on a like-for-like basis, the NLR-RB 19E was found to be cheaper, but in a real-world comparison with the larger aircraft that it is more likely to compete against in the marketplace, the sub-regional electric aircraft was indeed more expensive. The most direct solution to address this additional cost would be to subsidise airport charges for electric aeroplanes. This would enable multi-for-one journey replacement, making the NLR-RB 19E competitive against larger aircraft.

Pros and cons

Having tackled the all-important question of cost, we must also consider more qualitative factors: electric aircraft of this size could be advantageous in many other areas. Being quieter and smaller, they could open up access to smaller airports, enabling distributed aviation, where small regional aircraft connect regional airports en masse, taking the point-to-point philosophy a step further. For travellers currently forced to take interconnecting flights, the NLR-RB 19E could enable more direct flights, which is more convenient, and reduce total travel time and potentially lower the costs. At scale, distributed aviation might even allow larger aircraft to focus entirely on longer-haul journeys, improving their own CO2 footprint emitted for each revenue passenger-kilometre (RPK) and leaving shorter distances for these small, electric sub-regional aircraft. However, it will be difficult to replace the larger planes.

The key learning point from our investigation is that larger options, such as A320-type aircraft, are more efficient for instance in terms of airport charges and would have greater potential. Royal NLR and Roland Berger are therefore now planning to turn their attention to the narrow-body scale, looking beyond pure-electric aircraft (which would not be feasible on this scale) and considering new designs. Calculating their commercial, real-world impact lets us gain a practical understanding of future sustainability in the industry.

This article has been produced by NLR and Roland Berger. It was drawn up by Wim Lammen (Senior Scientist at NLR) and Nikhil Sachdeva (Senior PM at Roland Berger).