SUSTAINability increase of lightweight, multifunctional and intelligent airframe and engine parts

SUSTAINair is addressing the major challenge of making aircraft more sustainable. The research project focused on new technologies, materials, manufacturing processes and systems to achieve a paradigm shift to a circular approach of aircraft design and manufacturing. Aircraft need to become more recyclable from design, manufacturing and operations through to End of Life (EoL) and this will in turn strengthen competitiveness and leadership of the European aerospace and aviation industry.

The challenge

The new circular design and manufacturing approach requires more insight in how to use and join recycled (2nd life) materials and approaches on how to repair them.

The solution

Key Enabling Technologies (KET’s) that need further development (from TRL 2 to 4), in which NLR had a primary role:

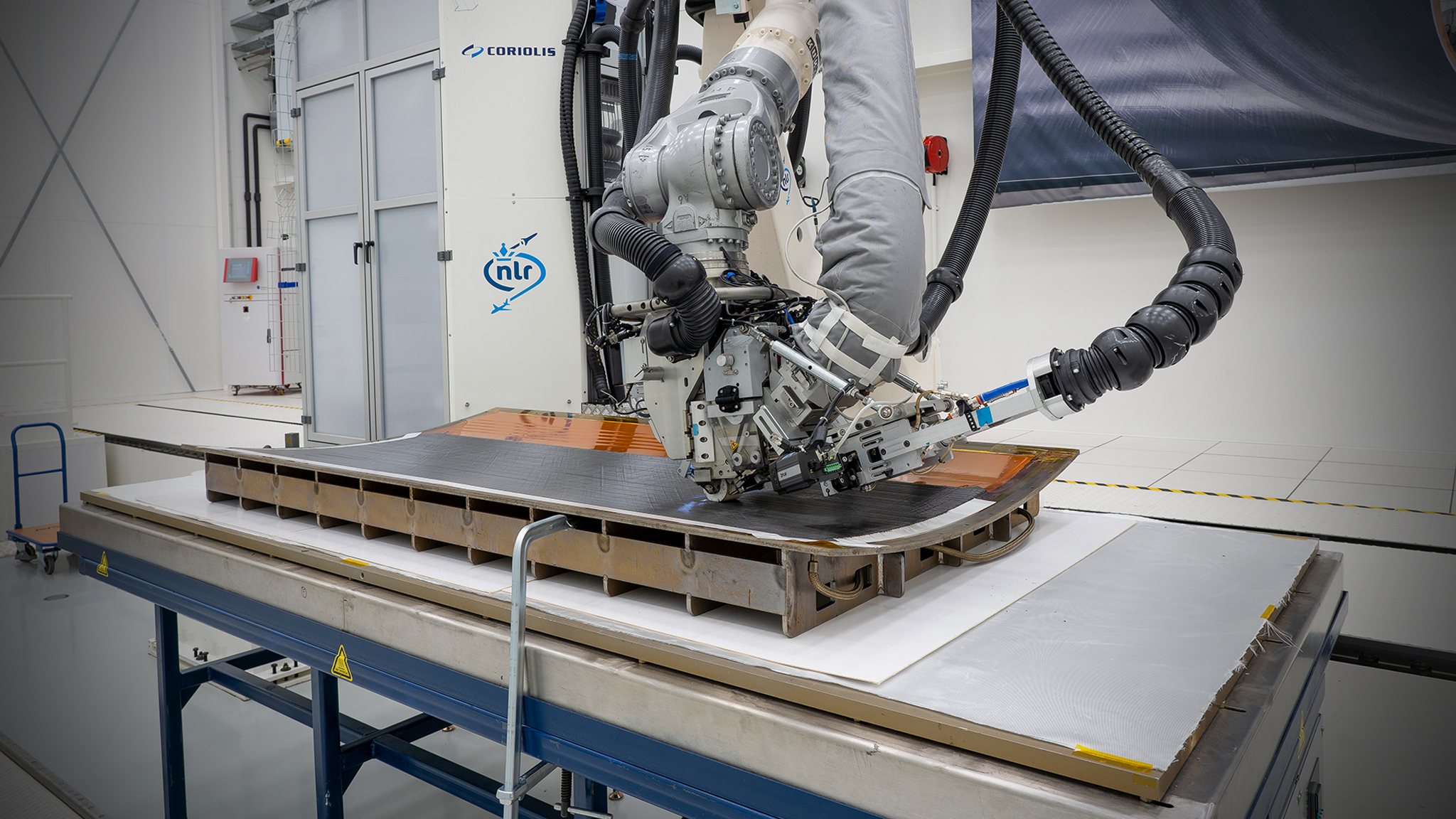

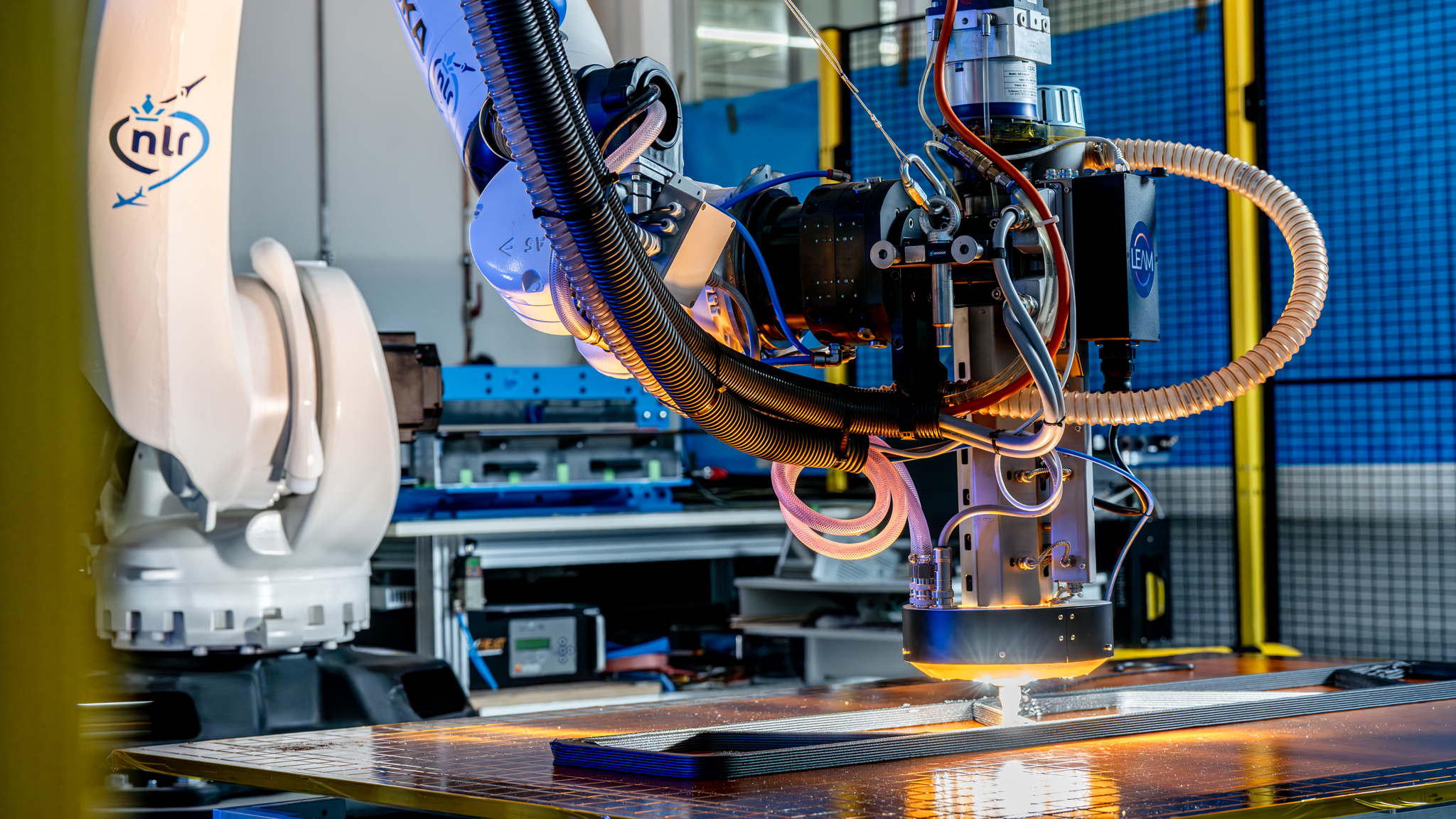

- Induction welding of recycled thermoplastic material, both for initial joining and repair

- Thermoplastic induction welding temperature monitoring, via optical fibres

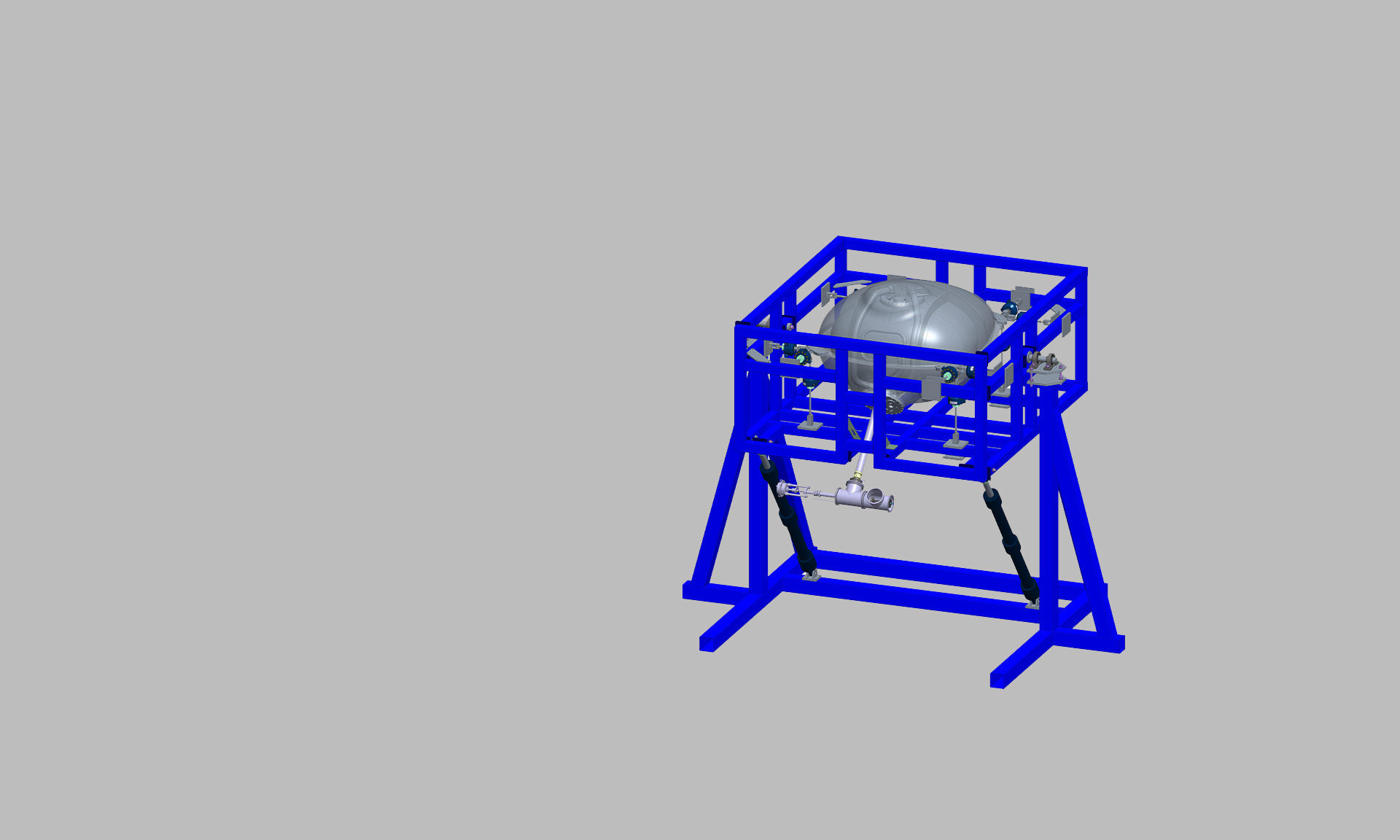

- Aircraft dismantling by developing and demonstrating a rivet removal robot

What we are doing

NLR worked on welding of test panels made from both 1st and 2nd life thermoplastic PPS and LM-PAEK materials. The welding turned out to be possible, however more variety in terms of weld temperature was found because of the non-uniform character of the 2nd life material. Optical fibres were integrated to measure the temperature during welding via bragg gratings. This technique also has potential to use with a direct feedback loop on process settings, especially important for welding of 2nd life material. The findings were used as an input for the design of a demonstrator, for which both 1st and 2nd life and also optical fibres for online monitoring were used.

The demonstrator clearly shows the potential of using 2nd life materials in the future to aid circular aircraft design.

Induction welding was also successfully used to perform repairs on LM-PAEK scarfed patches.

NLR set-up a LCA-framework to compare the different manufacturing approaches and materials with each other, to be applied onto the manufacture process of future high TRL-components so the potential of using 2nd life materials can be justified.

Finally, NLR also helped in developing autonomously rivet removal by studying which detection techniques for the rivets works the best and by extracting coordinates of the rivets, to be used for the rivet removal afterwards by other consortium members.

Project partners:

Research organisations : Royal NLR, (DLR, Joanneum, AIT-LKR)

Industry (NL) : Collins-DTC, AELS

Industry (EU) : RTDS, INO, INVENT

Universities : TU Delft, JKU

Co-funded by Horizon Europe 2020, GA no. 101006952