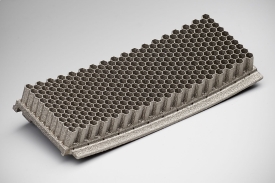

SLM produced article

As so many already predicted, 3D printing is unleashing an economic revolution. On the one hand, this production technology has significant logistical advantages. 3D printers allow for local manufacturing of components, eliminating the need for expensive and unsustainable transportation of components. On the other hand, the innovative printing technology also offers significant intrinsic advantages compared to traditional design and production methods. For example, 3D printing makes it possible to print products with a complex internal structure, which cannot be done using conventional production methods like lathing or milling. With the commissioning of a state-of-the-art Selective Laser Melting machine (a 3D metal printer), the National Aerospace Laboratory of the Netherlands (NLR) has secured a leading position in this promising high-technology field. The new SLM facility will allow Dutch industry players to gain easy access to and gain experience with 3D metal printing, combined with the other high-quality facilities and knowledge of NLR.

The 3D metal printer was developed by the German firm SLM Solutions and uses two lasers of varying intensity, one of 400 watts and the other of 1,000 watts. The printer is capable of melting metal powders of various compositions, ranging from “ordinary” steel and aluminium to titanium, cobalt-chromium and nickel alloys. This so-called Additive Manufacturing process builds up products layer by layer, on the basis of a 3D design.

One appealing example of the capabilities of an SLM printer is the creation of a “spiral staircase”inside the rooks of a chess game. However, a virtually infinite number of truly practical applications are conceivable in the aviation industry. For instance, the printing process makes it possible to manufacture complex fuel lines or weight-saving cavities in metal engine components of aircraft or missiles, in critical hydraulic hardware or in supporting hull structures.

The possible applications are not just limited to the aviation sector. 3D printing can also be applied on a large scale and in creative ways in the automotive and related industries. The medical sector, too, is considering applications like organically shaped prosthesis components, implants and various applications for bone surgery. No one doubts that the diversity and scope of the applications of this technology will be impressive.

The printing process of this machine is far from familiar territory , not even for SLM Solutions. This is partly due to the relative lack of familiarity with the physical properties of the materials used. Briefly explained: the effects of the laser on the molten metal powders of different alloys are largely unknown. This gap in knowledge has to be closed. After all, the development of shrinkage cracks or other side-effects can be disastrous in the final application, especially in the aviation industry.

NLR has established a solid reputation, particularly in the field of high-precision materials research. The organization has decades of experience in the development of alloys and their subsequent testing for static and dynamic elasticity, robustness, reliability and other properties. The new SLM facility gives NLR the ability to gain fundamental knowledge of the technology, while at the same time developing future applications. NLR can also offer research support and assistance in starting up production to companies, both within and outside the traditional aviation market, precisely because of the diversity of all the applications.

Also visit out Additive Manufacturing capability page.