The facility provides dedicated support to companies developing lightweight systems using composite materials and/or metal. NLR offers comprehensive support throughout nearly all phases of product development, ranging from concept studies and material screening to detailed design preparation and concept creation. The centre also offers repair services and full-scale prototyping capabilities, allowing companies to bring their ideas to life. To facilitate seamless operation, users can choose to receive training or hire an experienced NLR operator to assist with equipment operation.

Main features

Equipment for manufacturing composite components

- Preform cell

- Resin transfer moulding station

- Eurocarbon overbraiding machine

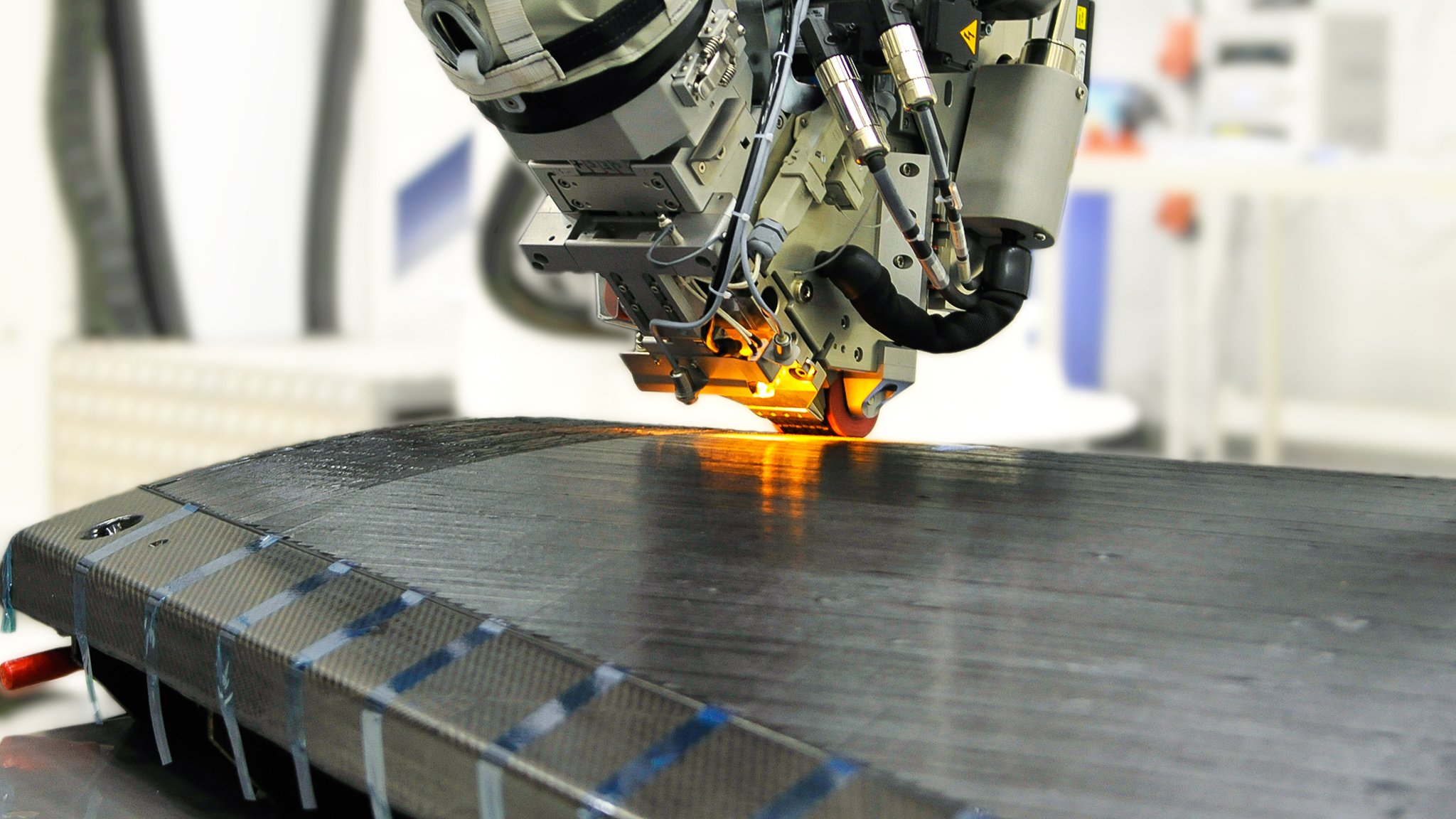

- Induction welding

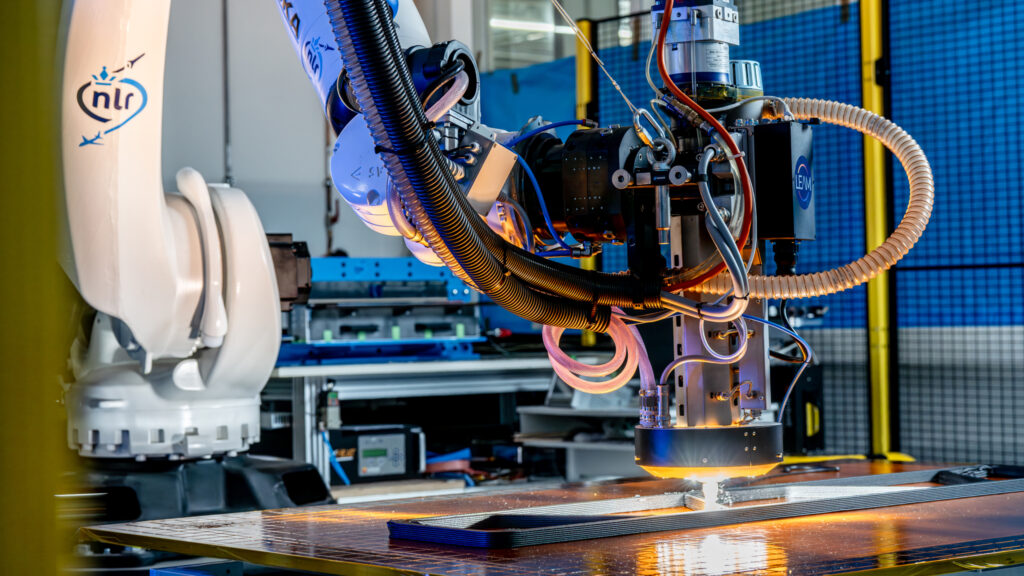

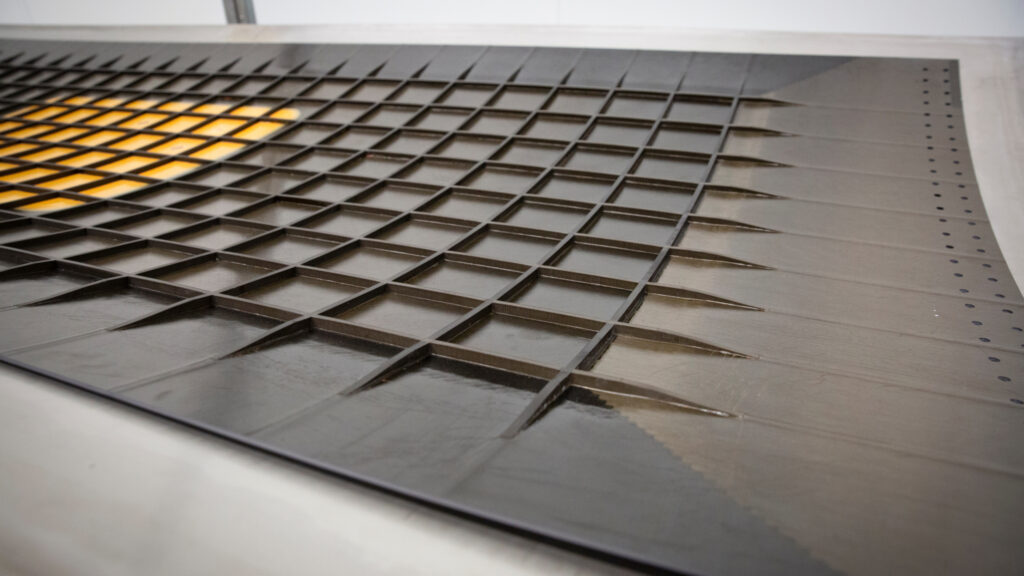

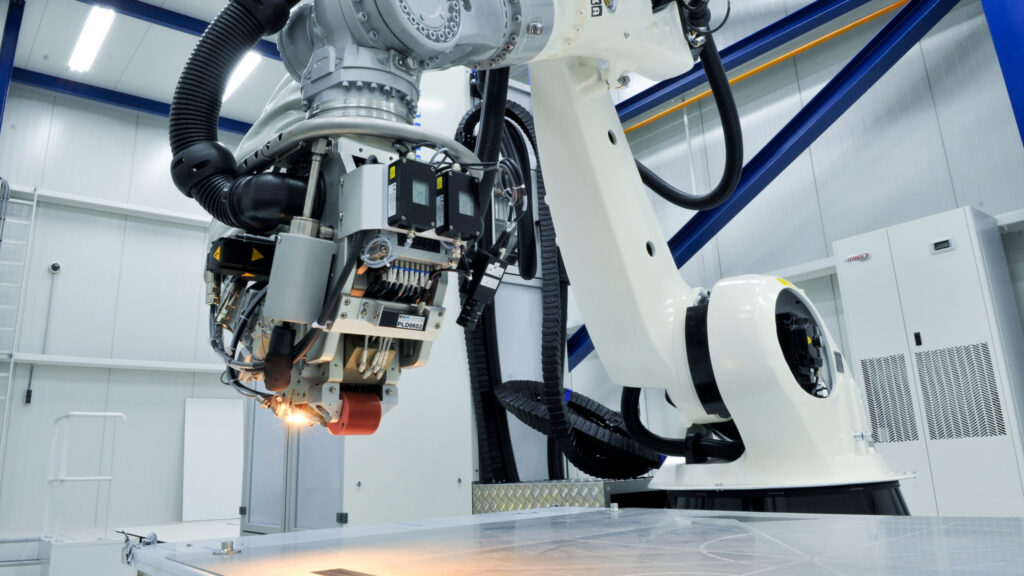

- Automated fibre placement machine

- Autoclave

- Heated press

- Large curing oven

Equipment for analysis and characterisation

- Rheometer

- Differential scanning calorimeter (DSC)

- Thermogravimetric analysis (TGA)

- Supporting software

- Non destructive inspection (NDI)

Equipment for additive manufacturing

- Laser Powder Bed Fusion (LPBF)

- Blown Powder Directed Energy Deposition (manufacturing & repairs)

- Sinter-based fused filament fabrication

- Materials laboratories and research & testing facilities

- Large scale additive manufacturing