We can assist you in manufacturing and machining your test articles and help you to set up a test plan. Our simulation, engineering, manufacturing and machining capabilities enable us to provide you with the best tooling and test setup structure:

- Standardised tests, material qualification, certification tests, or tests made fit for your purposes

- Mechanical or environmental testing

- Materials of the test articles: ceramic, composite or metal

- Sizes: small up to full scale

Main features

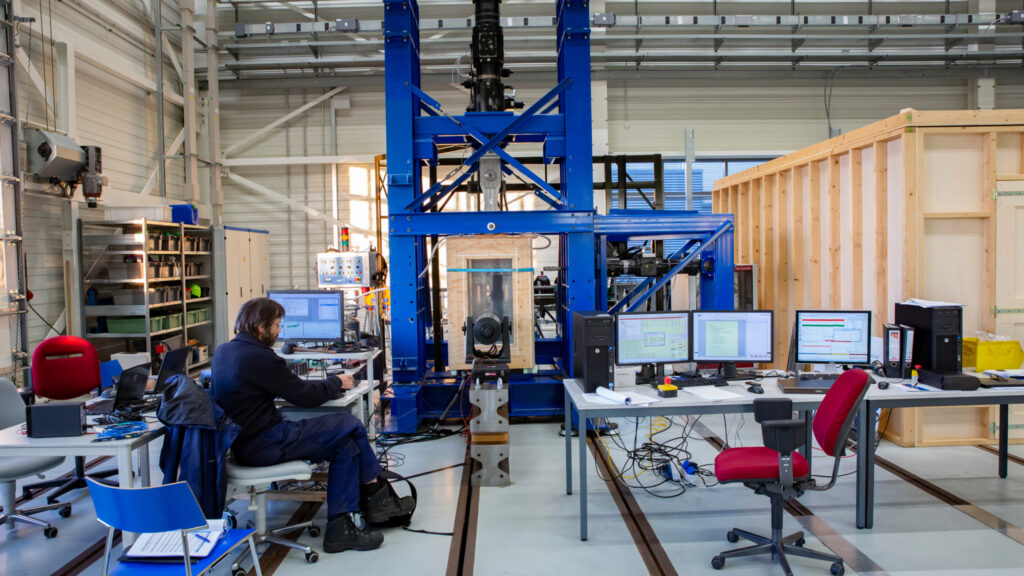

Mechanical testing:

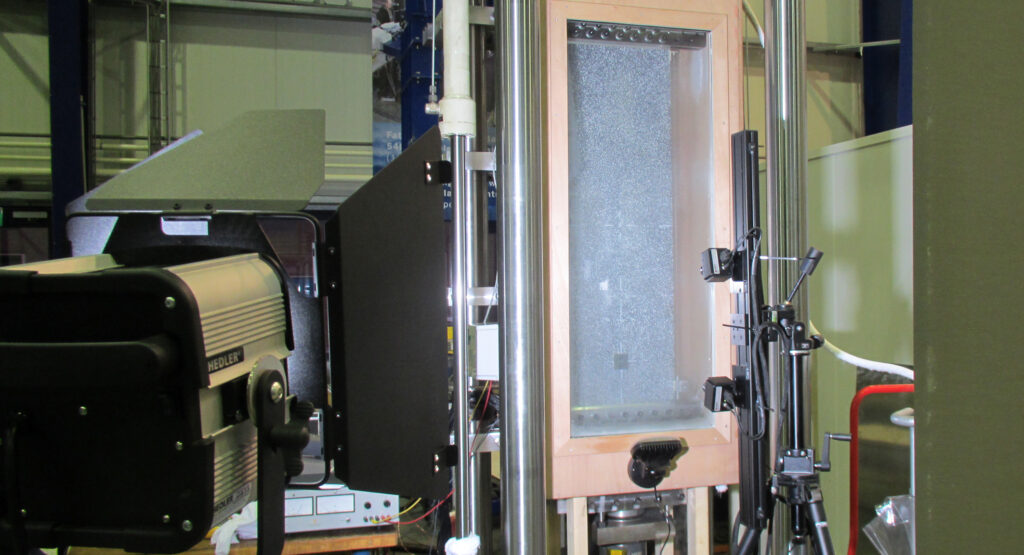

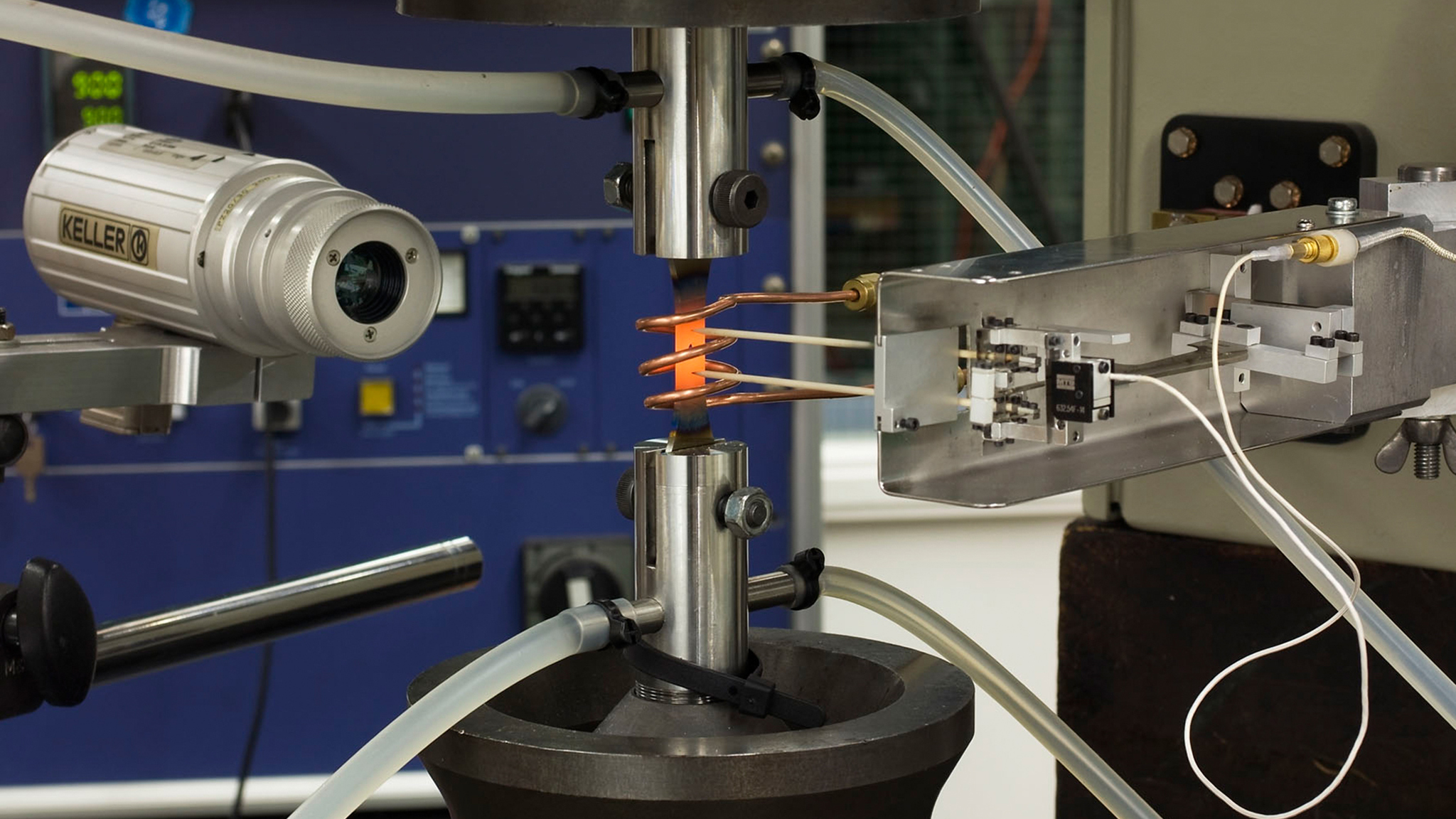

- Coupon and materials testing static, fatigue and damage tolerance testing according to international standards or customer specifications. Materials testing, evaluation and qualification programs.

- Ambient, (deep-) cryogenic or elevated temperatures; dry, wet or chemically enhanced. Chemically enhanced ranges from (toxic) oil and gas related substances to (liquid) hydrogen.

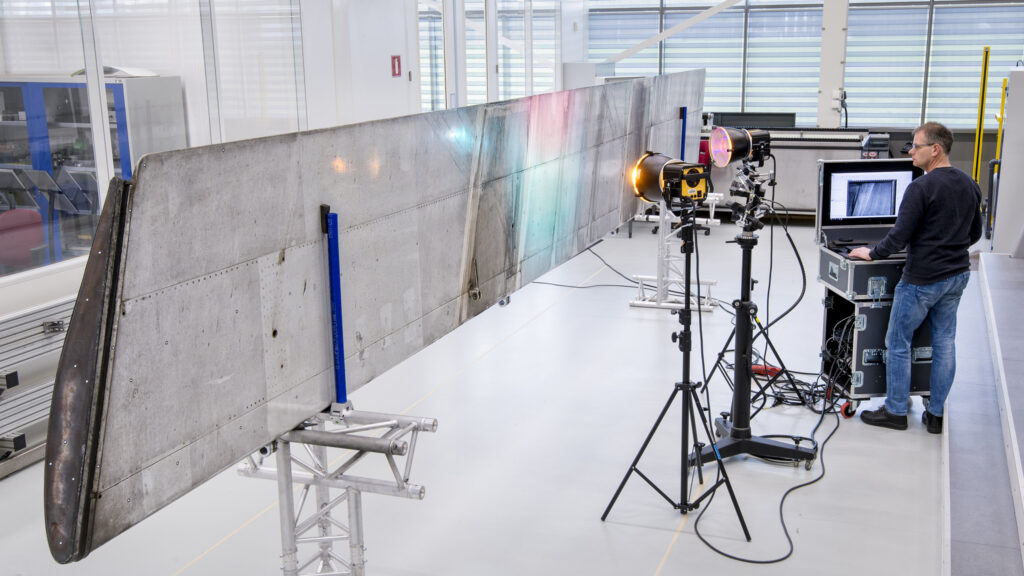

- Panel and component testing Large complex component testing, shear / compression buckling, fatigue and damage tolerance testing, curved fuselage panel testing.

- Ambient, cryogenic or elevated temperatures; dry or wet. Full scale testing, certification or research Load spectrum generation, rig design, testing and inspections of aircraft parts like moveables up to full wings or tails. Ambient, cryogenic or elevated temperatures; dry or wet

Environmental testing:

- Testing of materials and systems under various environmental conditions.

- High/low temperature, humidity, salt spray, decompression, altitude and waterproofness testing.

- Vibration, shock, acceleration, electric and acoustic environmental tests

Material evaluation:

- Failure analysis, materials failure and corrosion analysis, metallurgical services and forensic engineering.

- Material failure analysis is performed mostly both post-mortem but also in-situ.

- Non destructive inspection fully automated C-scans, submerged and squirter mode, single beam and phased array, Eddy current, ultrasound, dye penetrant, thermographic, shearographic, 3D structured light and magnetic inspection.

Measuring, control and calibration:

- Calibration according to ISO 17025 of test machines or equipment, measuring and control technology.