NLR has more than 50 years of experience of metals, which according to Marc de Smit, NLR project leader at the Metal Additive Manufacturing Technical Centre (MAMTeC) is incredibly important for additive manufacturing research, together with knowledge of aircraft certification. “We were immediately able to bring those 50 years of knowledge into MAMTeC”, says De Smit. “What we saw was that many companies did not initially understand what we were all about. They thought: you print in plastic, so surely you can also print it in metal? That’s obviously not how it works.”

To ensure that printed metal components meet the quality requirements of the aerospace industry, a four-year programme was set up in cooperation with TNO, Delft University of Technology, Twente University, Groningen University and numerous private sector companies with support from the Dutch Ministry of Economic Affairs. Together with these partners, NLR has already acquired a solid knowledge base for metal additive manufacturing. The logical consequence is that the production process can be certificated and is thus demonstrably reproducible, or in other words: exactly the same product will roll out every time. According to De Smit, this is possible only if you possess a thorough knowledge and understanding of the process.

Economically feasible

With the increased understanding of the printing process and subsequent reproducibility, applications using metal printed parts in aircraft components are becoming feasible from an economic point of view are now much closer. De Smit: “Of course, you can print the same thing twelve times in one print job, then test eleven of them and put the twelfth in the aircraft. But that obviously makes the twelfth component far too expensive. You want to be able to print such a component in large numbers, be able to detect production faults, and know for certain that approved components can be fitted in the aircraft.”

Enormous difference in quality

Even with a relatively new branch of technology like MAMTeC, good old-fashioned knowledge of materials is by no means superfluous. Metal powder is used as a raw material in many additive manufacturing processes. NLR was able to demonstrate that properties of the used metal powder (composition and size and shape of the metal granules) can significantly influence the quality of the end-product. In practice, it is difficult to specify exactly what requirements a powder for 3D printing must meet. Nor is it easy to check whether a powder satisfies the defined specifications. MAMTeC is developing procedures to be able to check the quality of powders so that the same starting position can always be adopted for achieving the best quality.

From idea to commercial product

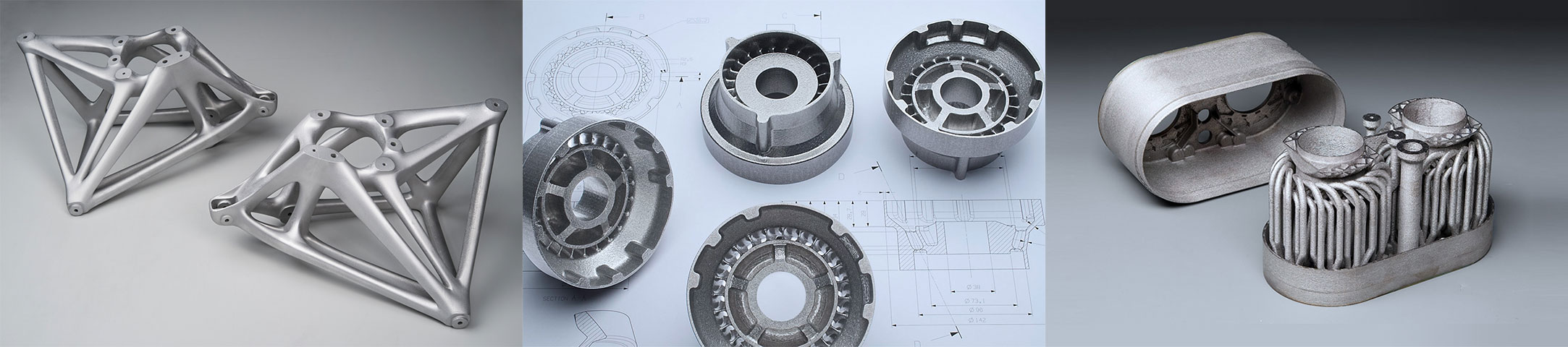

One of the main advantages of additive manufacturing is the great degree of design freedom. This process makes it possible to produce complex shapes and channels that would otherwise not be makeable. The design freedom allows the production of products that are lighter and can perform better. That is why additive manufacturing has opened up numerous opportunities in aviation, such as reduced energy consumption, lower emissions and a longer service life.

However, it is not always easy to recognise applications in which the advantages of additive manufacturing can be utilised optimally. The 3D printing process also has its limitations and specific design rules. MAMTeC is endeavouring to assist companies in identifying promising applications. The knowledge of design rules and optimisation are then used to translate an idea into an optimised commercial product.

A first for the Royal Dutch Air Force

The first printed product in the Netherlands by metal additive manufacturing that actually flew on a helicopter at year-end 2016 was a ladder mount for the NH90 helicopter of the Royal Netherlands Air Force. It is a coupling that is affixed to the helicopter and to which a ladder can be mounted so as to perform maintenance. Although hardly a critical part from an operational point of view, it was a good case to start with. “If the thing falls off, it won’t harm the helicopter, but it did show how it could be useful for an organisation like the air force”, says De Smit. Metal additive manufacturing also raises an important logistics-critical question for the air force, namely whether on a mission you can print parts locally instead of taking them with you or having them sent out.

The 3D-printed ladder bracket is 40% lighter but stronger and more durable than the original design. 3D printing enables the Royal Netherlands Air Force to have parts produced faster, reduce maintenance costs, and at the end improve the deployability of her weapon systems. The Royal Netherlands Air Force commissioned the development of the ladder bracket. The project was a collaborative venture, with Fokker Aerostructures responsible for engineering, NLR-Netherlands Aerospace Center for 3D printing and testing, BPO-Delft for redesign and the Defence Materiel Organisation for certification.

NLR is receiving more and more new questions about additive manufacturing, such as the production of products that are metres long. A business case is now being drawn up for a device in response to questions from the market.

More information

For more information about MAMTec:

Marc de Smit marc.de.smit@nlr.nl