28 January 2026

Innovation and Safety: the Future of Non-Kinetic Operations

Defence and safety are undergoing a period of fundamental change. The rise of new technologies is changing the nature of conflict, with a growing focus on non-kinetic activities such as cyber attacks, influence through social media, and the disruption and manipulation of electromagnetic signals. These developments pose new challenges for defence organisations, making it essential to find innovative solutions to ensure safety. NLR supports Defence with knowledge and expertise to remain effective in non-kinetic operations.

CHECK OUR NEWS IN BRIEF HERE

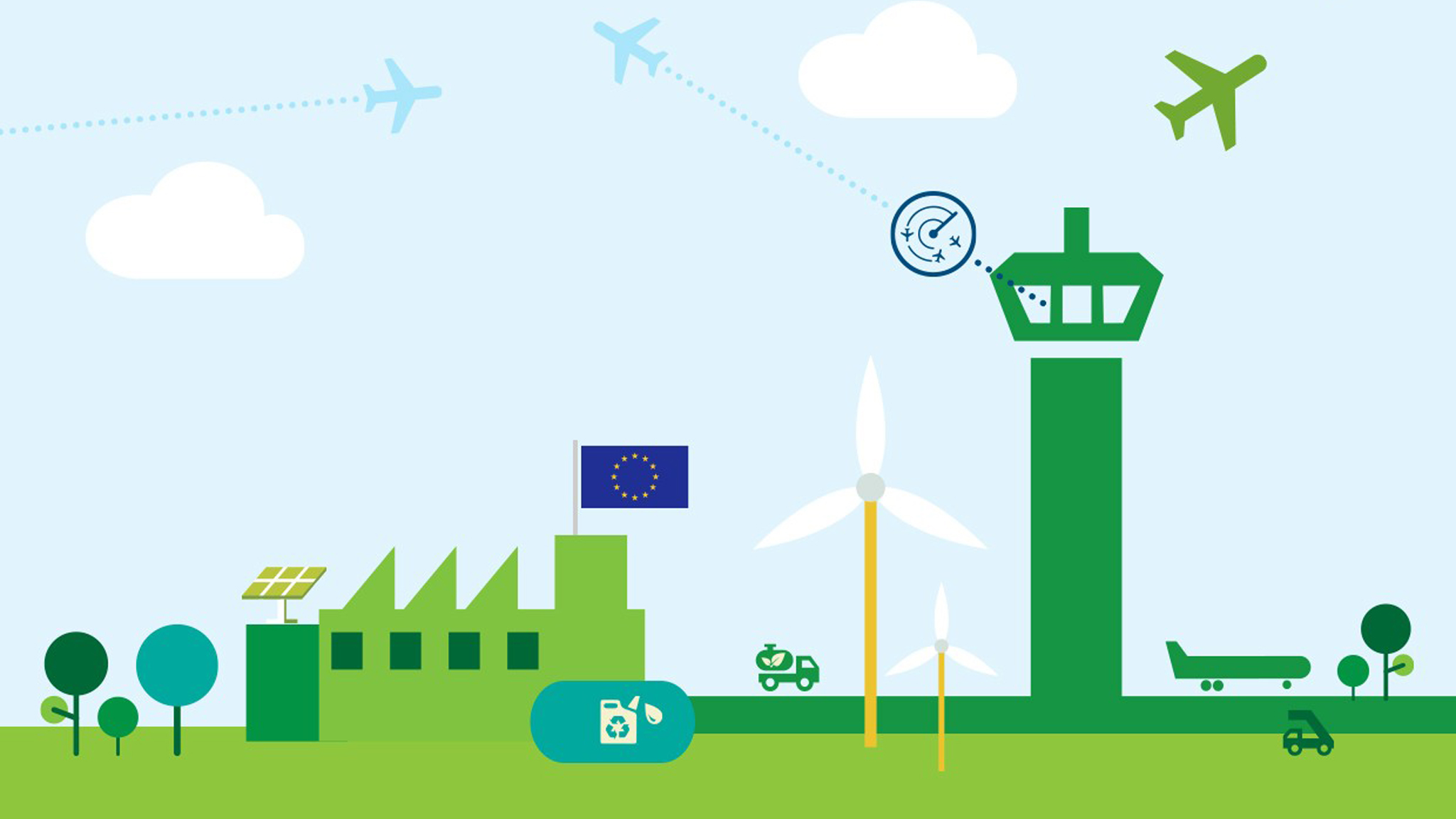

Sustainability and Environment

R&D case: Neutralising hazards for chromated aircraft scrap handling

AGENDA

Let’s meet!

3 -4 March

Amsterdam Space Symposium

10-12 March

JEC World

26-28 May

Airspace World

10-14 June

ILA Berlin

Areas of expertise

Programmes

Markets

NLR Repository

Newsroom

Stay up to date with the latest developments. In the Newsroom you can find the latest news, articles, and blogs from NLR. We also showcase a range of videos and publications here. For more video content, please visit our YouTube channel, NLRmedia.