NLR can help you achieve better aircraft component design in less time and at lower costs. Our expertise enables product improvement, weight reduction, and minimisation of production and maintenance costs, while ensuring compliance with environmental constraints. We focus on optimising critical components such as wings, control surfaces like flaps and tail planes, structural parts, fuselage panels, floor beams, and propellers. By leveraging our knowledge and capabilities, you can enhance the performance, efficiency, and sustainability of your aircraft components, ultimately increasing competitiveness and reducing environmental impact while improving overall safety and reliability.

NLR can support you with:

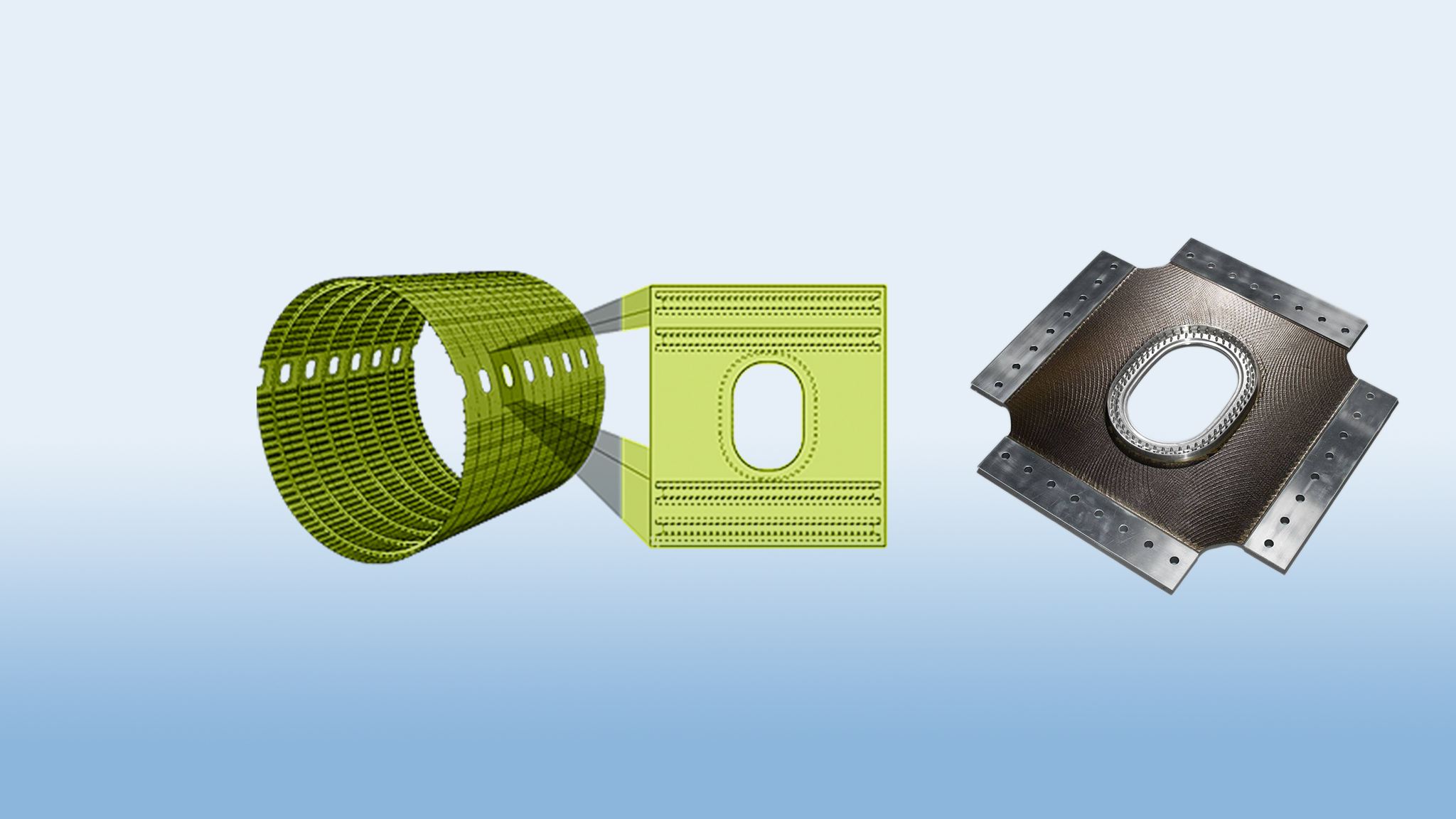

- Advanced design capabilities for structural parts, fuselage panels, floor beams, control surfaces (flaps, spoilers, horizontal and vertical tail plane), wings, and propellers, for metal and composites, including GLARE, as well as hybrid materials, suitable for associated manufacturing and assembly technologies.

- Design services for other components, including landing gear, power distribution, electrical wiring and interconnection systems, pneumatic systems, environmental control systems, and thermal control systems.

- Component design for newly developed aircraft, both SAF-powered and hydrogen-powered, as well as existing aircraft (retrofit, mainly military).

- Design and development of additional products, such as frangible airport equipment (e.g., approach lights, ILS tower) and space robotic arms.

- Design and testing methodological advice for various aerospace applications.