Building on our expertise in thermal analysis and testing, NLR offers a wide range of services and facilities for thermal analysis and testing, including qualified R&D and test engineers, thermal vacuum chambers, thermal laboratories, and specialised test facilities such as the THETA hydrogen test facility and the Two-Phase Test Facility. Our facilities are part of our environmental test facilities, allowing us to provide a complete one-stop test campaign. We collaborate with leading companies such as NanoSpace/REALTECHNOLOGIE AG and have access to a broad range of software tools, including ESATAN, ThermXL, Abacus FEA, Matlab, Mathcad, and Labview. Our customers include major players such as AMS02 (CERN), NASA, ESA, Stork Fokker Elmo, ASML, Thales, Bradford Engineering, and Dutch Space. One of our notable successes is the development of the Tracker Thermal Control Cooling system for AMS02, a two-phase cooling system that has been operating successfully on the International Space Station (ISS) since May 2011.

NLR can support you with:

- Cost-effective development of dedicated thermal control systems (10 W-100 kW)

- Two-phase heat transport systems (two-phase pumped loops, loop heat pipes, pulsating heat pipes, vapour chambers)

- Design, modelling, prototyping, development testing and qualification of satellite and aerospace cooling systems.

- Two-phase accumulators for space applications (see our parabolic flight movie).

- High end (aero)space pumps or micro-pumps for small satellites.

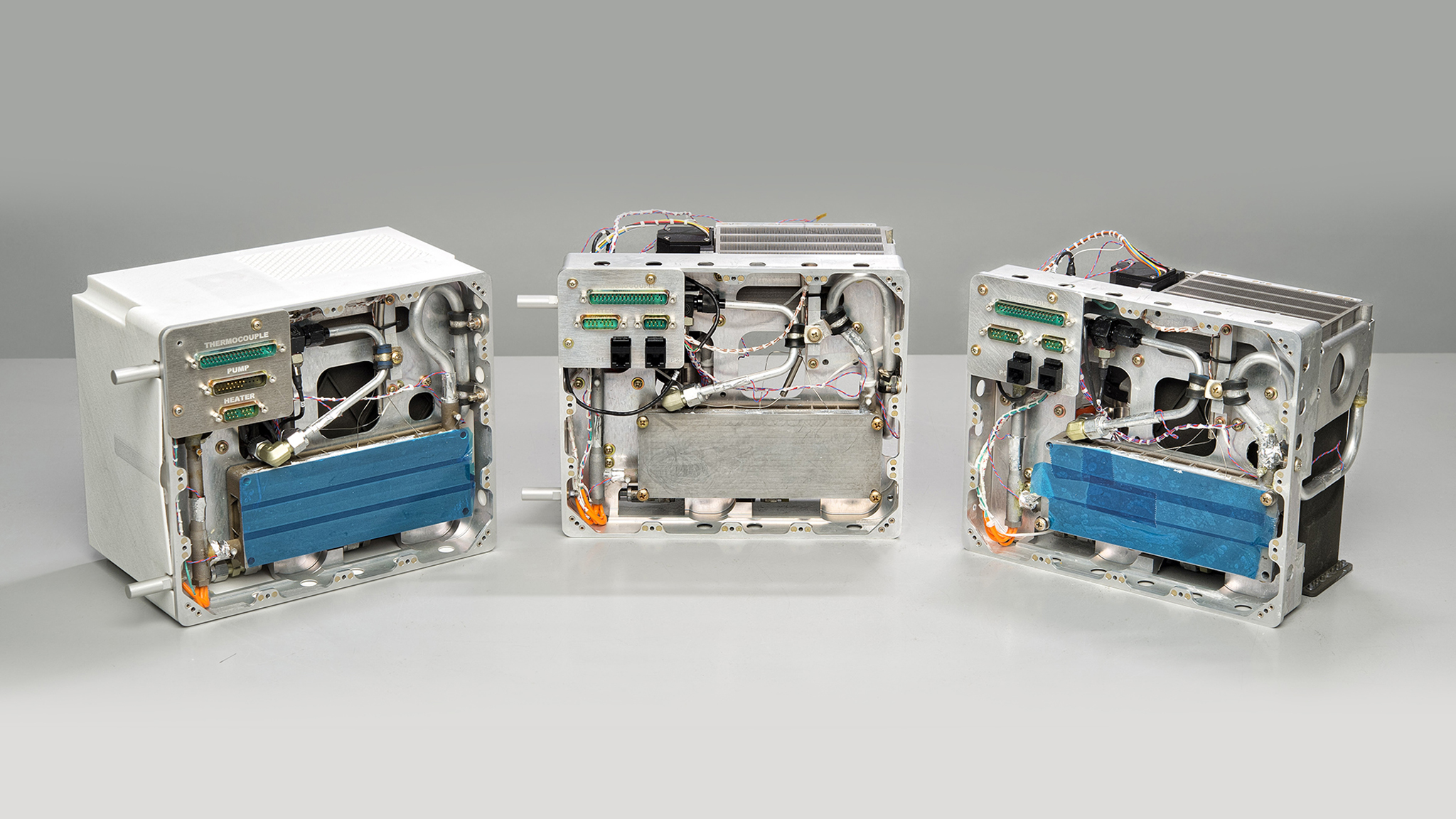

- Lightweight and mini thermal control systems (read our papers on mini Mechanically Pumped Loop Modelling (MPL) and design for standardized CubeSat thermal control or micro-pumped cooling loop to standardize micro-sat thermal control).

- Conductivity testing of carbon fibre panels.

- Design and delivery of filling systems for heat pipes, cooling systems and spacecraft storage tanks.

- Thermal modelling and testing of aerospace wiring for harness mass reduction.

- Fuel cell thermal control for aircraft applications.

- High thermal stability thermal control systems (mK-level).