Composites play an increasingly important role in aircraft design. MAAXIMUS aims to support the European aircraft industry in the production of lighter, stronger, more robust composite aircraft components.

NLR is playing a leading role in an ambitious European Union programme to support the European aviation industry. This programme – More Affordable Aircraft through eXtended Integrated and Mature nUmerical Sizing (MAAXIMUS), aims to produce lighter, stronger, more robust composite aircraft components.

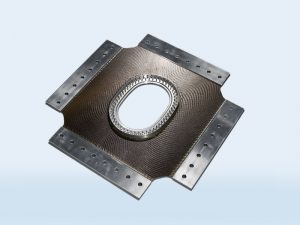

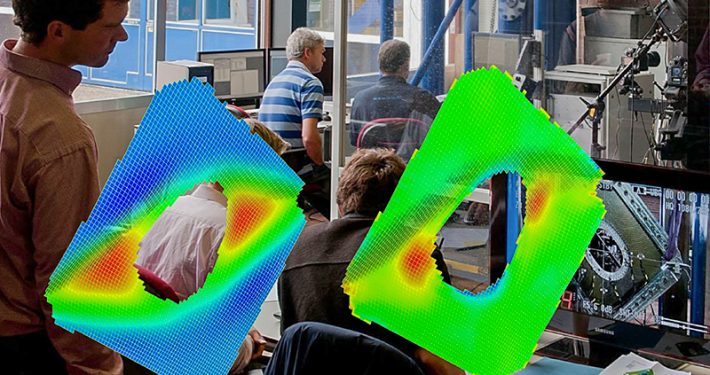

NLR has a dual role in MAAXIMUS, which is scheduled to run until 2013. On the one hand, we play a leading role in the management of this programme, which also includes NLR’s sister institutes and key European aircraft industries. This broad collaboration is necessary to meet the project’s targets: the development of an innovative composite fuselage for a medium-sized aircraft, including window panels and floor sections. On the other hand, NLR is involved in developing substantive aspects of technology. Our activities in this regard primarily focus on two areas: first, the development and application of numerically optimised algorithms; and second, the advancement of the Automated Fibre Placement (AFP) production process.

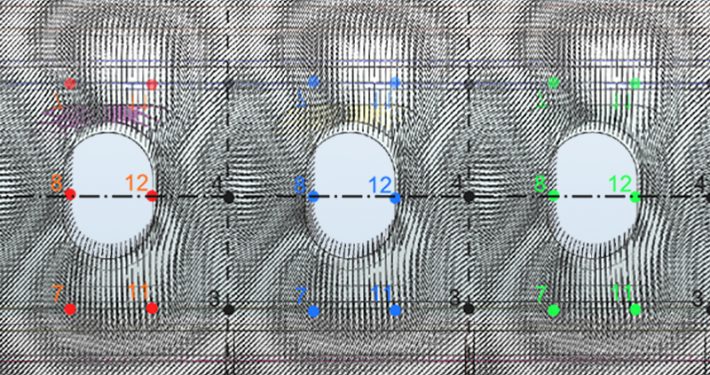

In 2011, NLR adopted a multidisciplinary approach in designing, constructing and testing a composite window panel. This led to new insight into fibre-placement technology, a process whereby fibres are bent into the matrix of the composite material, allowing the production of curved components. This is an enormous leap forward compared to the traditional method in which fibres are applied to the matrix in a flat braid. NLR has succeeded in translating this new method of fibre placement into production methods that can be immediately applied. This is not only important for the European airline industry, but certainly also for Dutch suppliers in this branch.