The Dutch aviation industry aims to maintain its role in the global market. One innovative project with great market potential is the development of a new composite flight control component – the flap on the trailing edge of an aircraft wing.

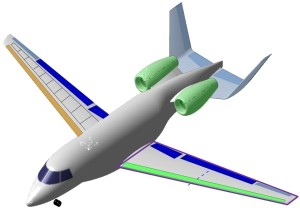

The development of these flaps is part of the Clean Sky Joint Technology Initiative, an ambitious European programme aimed at making aviation more sustainable through new technologies and materials. ‘Smart Fixed-Wing Aircraf’ is a Clean Sky project encompassing a series of innovative designs for the wings and tails of airliners and business jets. The ultimate goal is to develop ‘technology demonstrators’ that are scheduled for launch around 2015.

Fokker Aerostructures designed the flap concept in cooperation with Dassault Aviation of France, a company that has been designing and building business aircraft for decades. The flap was designed to create greater lift and is much lighter than the current generation of aluminium flaps. It has a geometrically challenging form with complex kinematic mechanisms allowing more flexible movement. These features make it possible to curb emissions and reduce noise production. It is precisely this complexity that calls for all aerodynamic and structural properties of the flap to be meticulously calculated. NLR is providing this specialist expertise to assist the aviation industry in developing these next-generation flaps.

This project sees NLR collaborating with producer Fokker Aerostructures and suppliers Airborne and Axxiflex Turbine Tools.