Programme

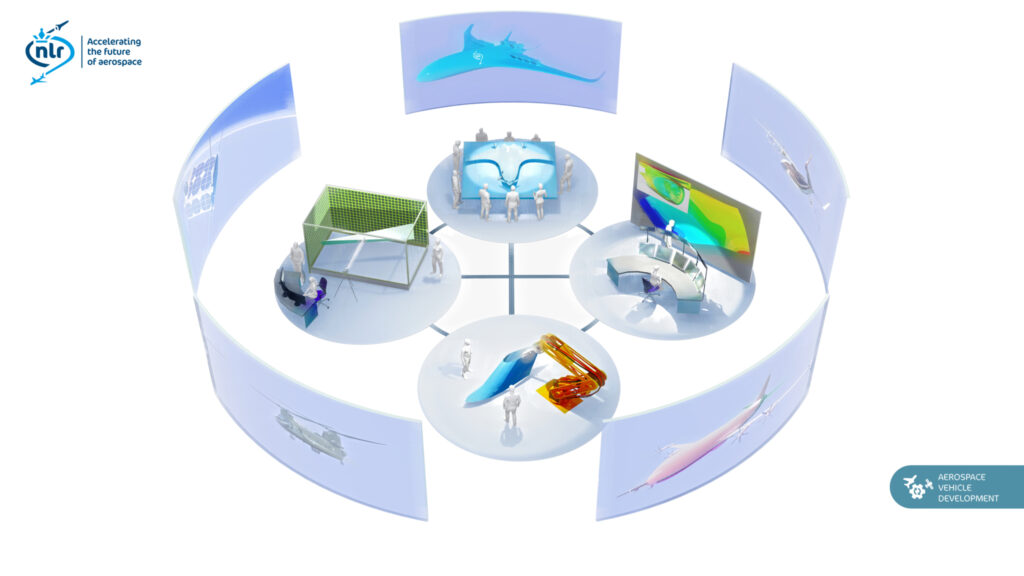

Development of air and space vehicles

NLR wants to enable the Dutch aerospace industry to have a competitive share from 2025 – 2050 in the development and production of the next generation low emission aircraft, in programmes for the next generation helicopters, in new small satellites, launchers and space applications, and in new flight concepts. NLR also wants to build knowledge to support Defence in the evaluation of military aircraft when purchasing new types, and in assessing the effects of new technologies on aviation safety.

“ Sustainable innovations in aviation for the Netherlands as a whole”

Programme leader Johan Kos on the Development of air and space vehicles knowledge programme

We want to do this by accrueing knowledge about the development of innovative products for air and space vehicles for business and the government. The programme primarily focuses on the development of innovative electronics, systems, instruments and lightweight materials and constructions for the aerospace industry.

Some projects

STUNNING

The STUNNING project (Smart Multi-Functional and Integrated TP Fuselage) focuses on developing a multifunctional and integrated fuselage made of thermoplastic composite material for large aircraft used for short to medium-haul flights. To achieve this goal, further work has been done on developing induction welding technology for joining thermoplastic components. This involved completing an experimental Technology Readiness Level (TRL) program, which tested process variations and performed mechanical tests on various specimens, including those with lightning strike protection. Additionally, work has been done on simulating the induction heating of laminates during welding, using a test program that evaluated different laminates with various build-ups.

Furthermore, simulations have been conducted on the process chain of the wire-based laser metal deposition process for a bracket, determining the effect of process steps on the fatigue life of the bracket. Finally, the model for crack growth in thermoplastic fuselage panels has been validated. These advancements aim to support the development of a lightweight, efficient, and durable fuselage for future aircraft, enabling more sustainable and environmentally friendly air travel.

This project has received funding from the Clean Sky 2 Joint Undertaking (JU) under grant agreement No 945583. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Clean Sky 2 JU members other than the Union.

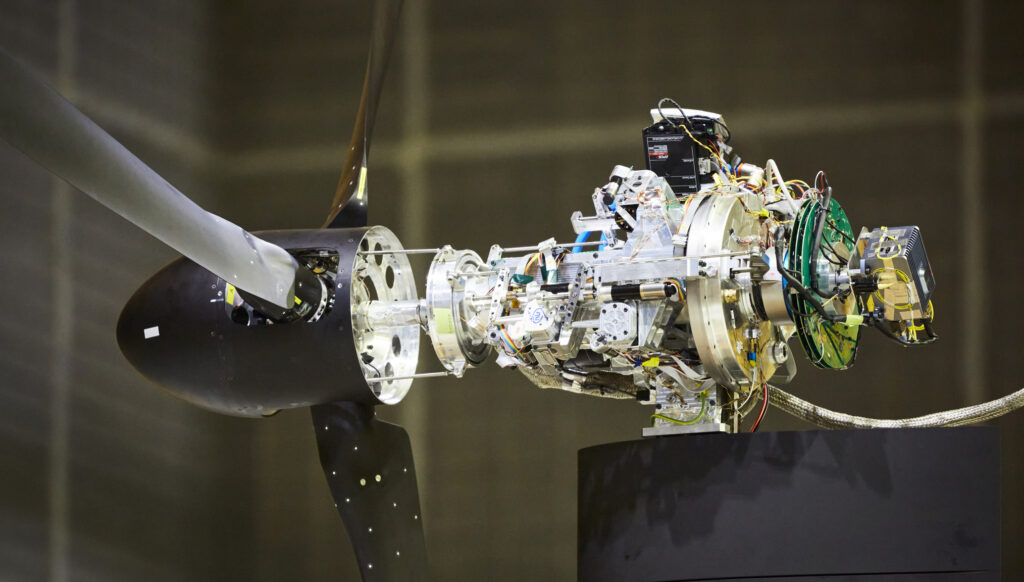

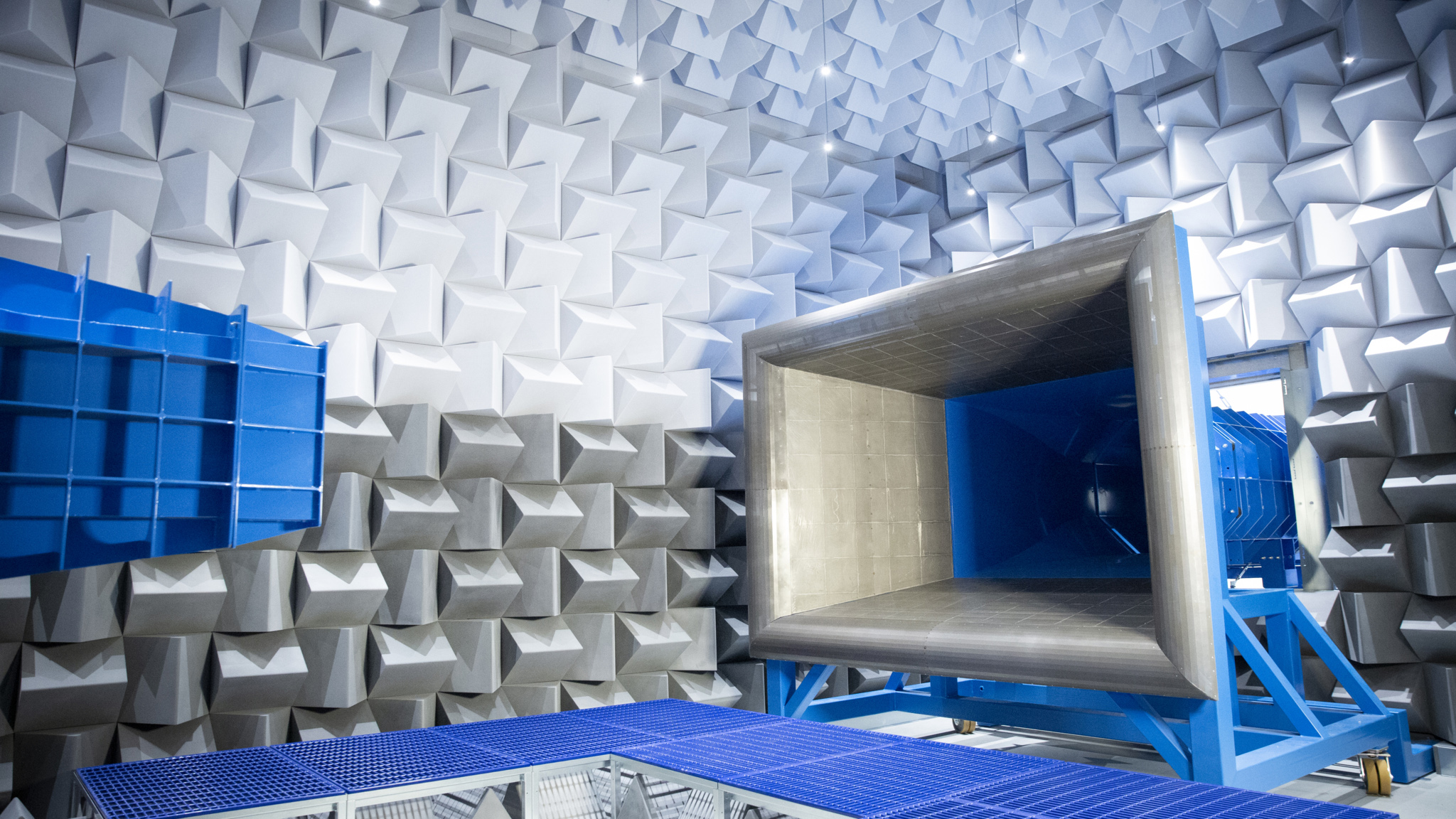

ATTILA

The ATTILA wind tunnel model (Advanced Testbed for Tiltrotor Aeroelastics) has been assembled, instrumented, and subjected to a series of ground vibration tests to characterise the dynamic behaviour of the test setup. The model was fitted with measurement equipment and was tested in the DNW LLF wind tunnel, where its flutter behaviour was investigated to expand the test envelope to the limits of stability. This test aims to validate numerical methods for predicting tiltrotor behaviour. Within this project, NLR is acquiring knowledge and experience in complex aeroelastic simulations and their integration with the design of aeroelastically scaled wind tunnel models featuring composite components.

This study has received funding from the Clean Sky 2 Joint Undertaking (JU) under Grant Agreement No 863418. The JO will receive support from the EU’s research and innovation programme Horizon 2020 and from the other members of the Clean Sky 2 JO.

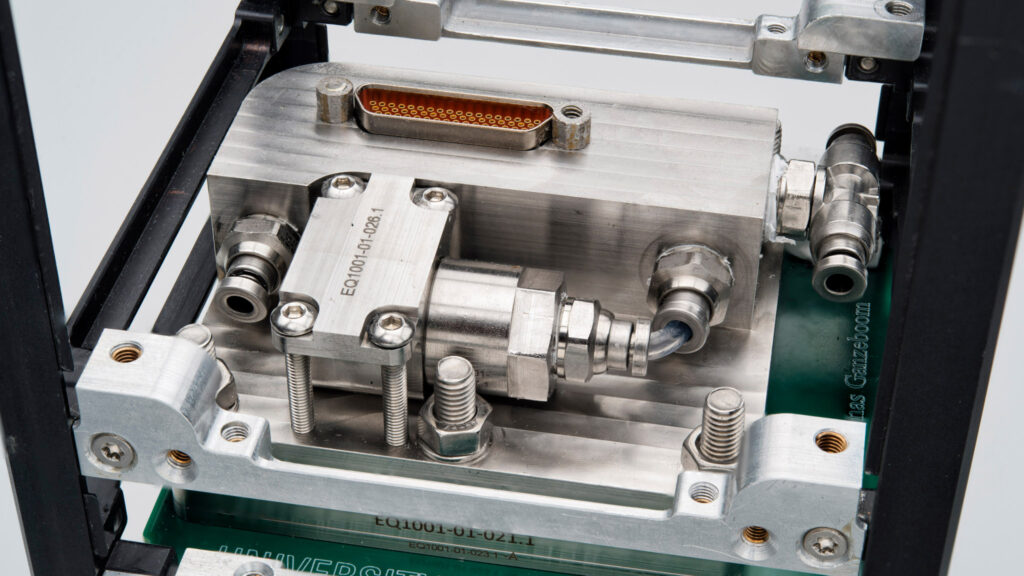

Mini-MPL

The Mini-MPL project aims to develop, test, and demonstrate a compact thermal management system for nano- and microsatellites. The end product is an Engineering Model that includes all necessary hardware for this system, including micropumps, fluid, and control electronics. The project is nearly complete, with all planned research and development activities finished and all components of the thermal loop, including control electronics, delivered.

The project may have a follow-up in the form of a demonstration mission in a real-world environment, called CASSINI IOD.

Discover more knowledge and technology

Research infrastructure

Areas of expertise