Maintenance technology

If you want to improve the productivity of your maintenance operation or if you are looking for solutions to solve personnel shortages, NLR can help. NLR creates smarter technologies by developing innovative soft and hardware tools and solutions. We create new maintenance resources and capabilities. We employ cutting-edge knowledge and technologies to automate maintenance tasks and processes using robotics, prognostics and artificial intelligence.

NLR can improve your productivity and help solve personnel shortages through automation. NLR offers solutions to reduce workload, overhead and administrative tasks. We develop autonomous inspection robots, and tools to analyse and predict component and system failures.

Products

NLR offers maintenance technology as a solution for MRO challenges:

FlexPlan – Flight schedule driven maintenance planning

FlexPlan builds efficient maintenance schedules and optimises the use of available maintenance opportunities between flights. It reduces downtime and maintenance costs

FD XAI – Failure Diagnostics using eXplainable Artificial Intelligence

FD XAI – uses eXplainable Artificial Intelligence (XAI) to identify failure modes and explain the diagnosis, even before the failure occurs. It helps troubleshooting and reduces no-fault-founds and shop time.

ARAI – Autonomous robot for aircraft inspections

Inspections are tedious and require highly trained technicians. These people can be difficult to come by. Now, envision the possibilities with robots that can assume some of the monotonous, dirty, and dangerous inspection tasks. Consider how this could improve the working conditions for your technicians.

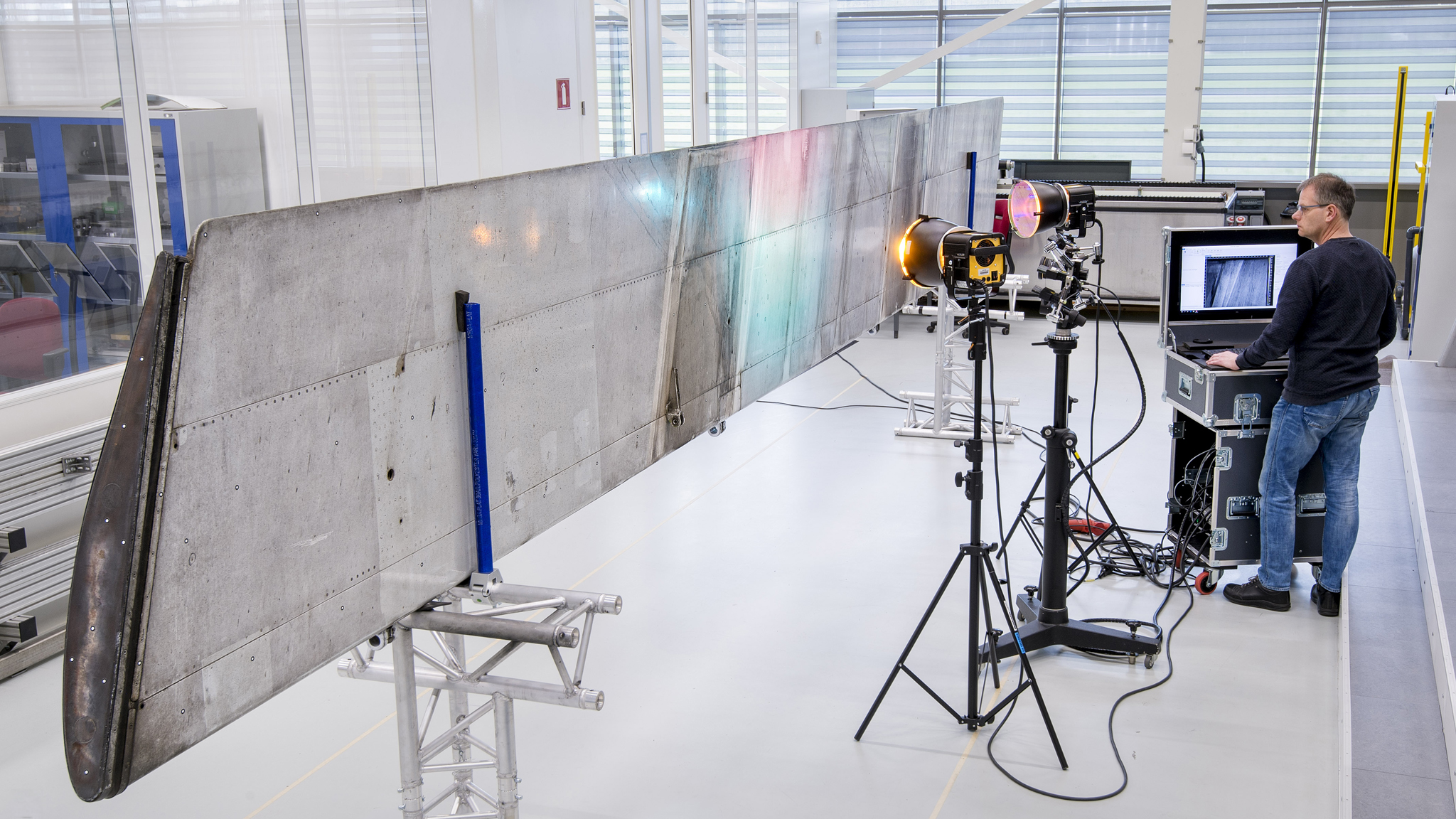

Leading Edge scanner – Autonomous visual aircraft inspections

How much time is consumed by the examination of leading edges? Incidents like hailstorms, collisions and damage pose a genuine risk to leading edge. It requires extensive inspections to measure the damage, resulting in downtime. Consider a robot capable of performing these inspections and measurements on your behalf.