Ultimaker, the global leader in desktop 3D printing, has an open material strategy which makes it possible to print applications with different materials with specific properties such as heat, impact and chemical resistance, flexibility, strength and more. Ultimaker 3rd party material suppliers deliver a wide range of reinforced (e.g. carbon or glass fibre) high performance plastics. These materials are delivered with optimised printing profiles from the Ultimaker Marketplace.

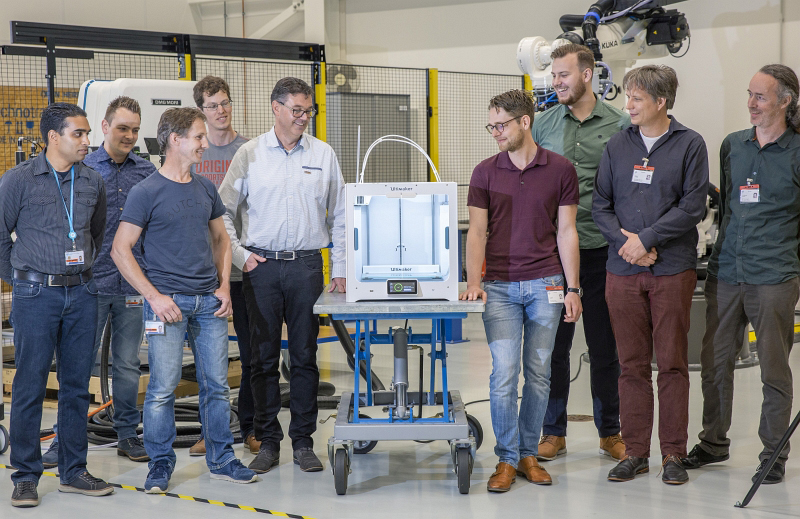

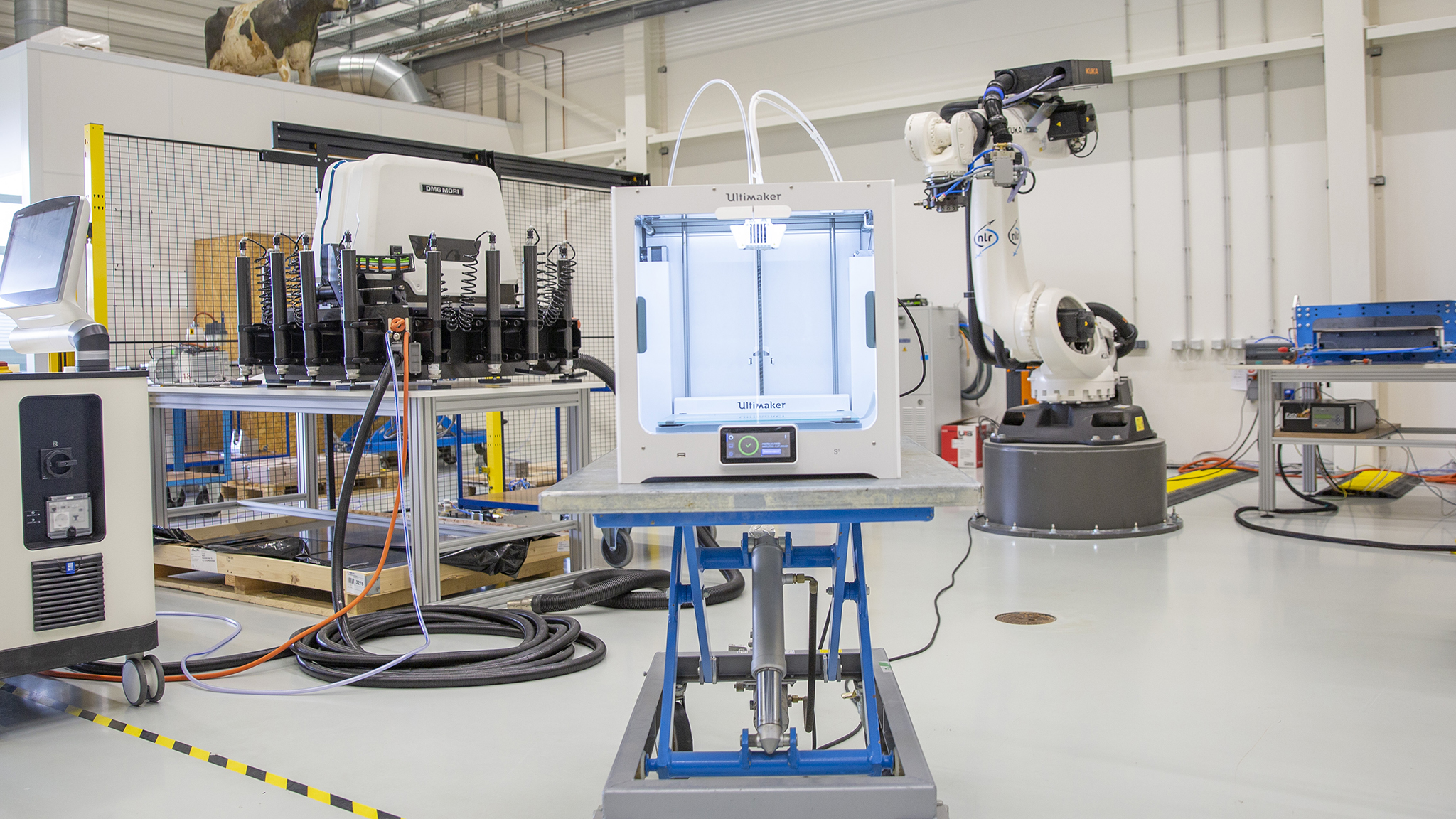

Besides processing fibre reinforced composites and additive manufacturing of high performance metals like aluminium, titanium, magnesium and inconel, ACM3 is expanding its reach on additive manufacturing by printing high performance (fibre reinforced) polymers like PEEK and PEKK and metal filaments. It is for this reason that NLR and Ultimaker decided to collaborate on this topic.

The collaboration will focus on improving the processability and material properties of these materials and will address topics like reproducibility and printing accuracy.

More info on ACM3 can be found

at https://www.nlr.org/article/high-tech-facilities-for-all/

This combination of NLR industrialisation expertise and Ultimaker print process knowledge will open up new possibilities for creating strong, multifunctional and lightweight parts. It will contribute to the establishment of 3D printing as a mature manufacturing technology, which can be made available to SME’s and industry.