In the “old days”, perhaps a decade ago, the aviation industry faced significant challenges from a highly competitive market and stringent environmental regulations. This meant that affordable and efficient aircraft had to be developed that were durable and easy to maintain. Fuel consumption and engine emissions were major concerns, primarily dependent on aircraft weight and gas turbine performance. The design phase focused heavily on evolutionary optimisations of the structural components and mechanical subsystems that made up the airframe, as well as the efficiency of fossil fuel-consuming engines.

Today, the focus has shifted towards minimising engine emissions to achieve net-zero emissions by 2050. This has led to a disruptive design paradigm shift, particularly towards sustainable aviation fuel (SAF) and, in Europe, hydrogen-based propulsion systems. With an eye on that second alternative to kerosene, NLR is focusing on energy storage solutions for large long-distance aircraft, so that liquid hydrogen can be safely stored and used as an energy source. The design phase now places emphasis on the thermal system design of the aircraft, and the (thermo-)mechanical design of the fuel system under deep cryogenic conditions of -253°C (20 K).

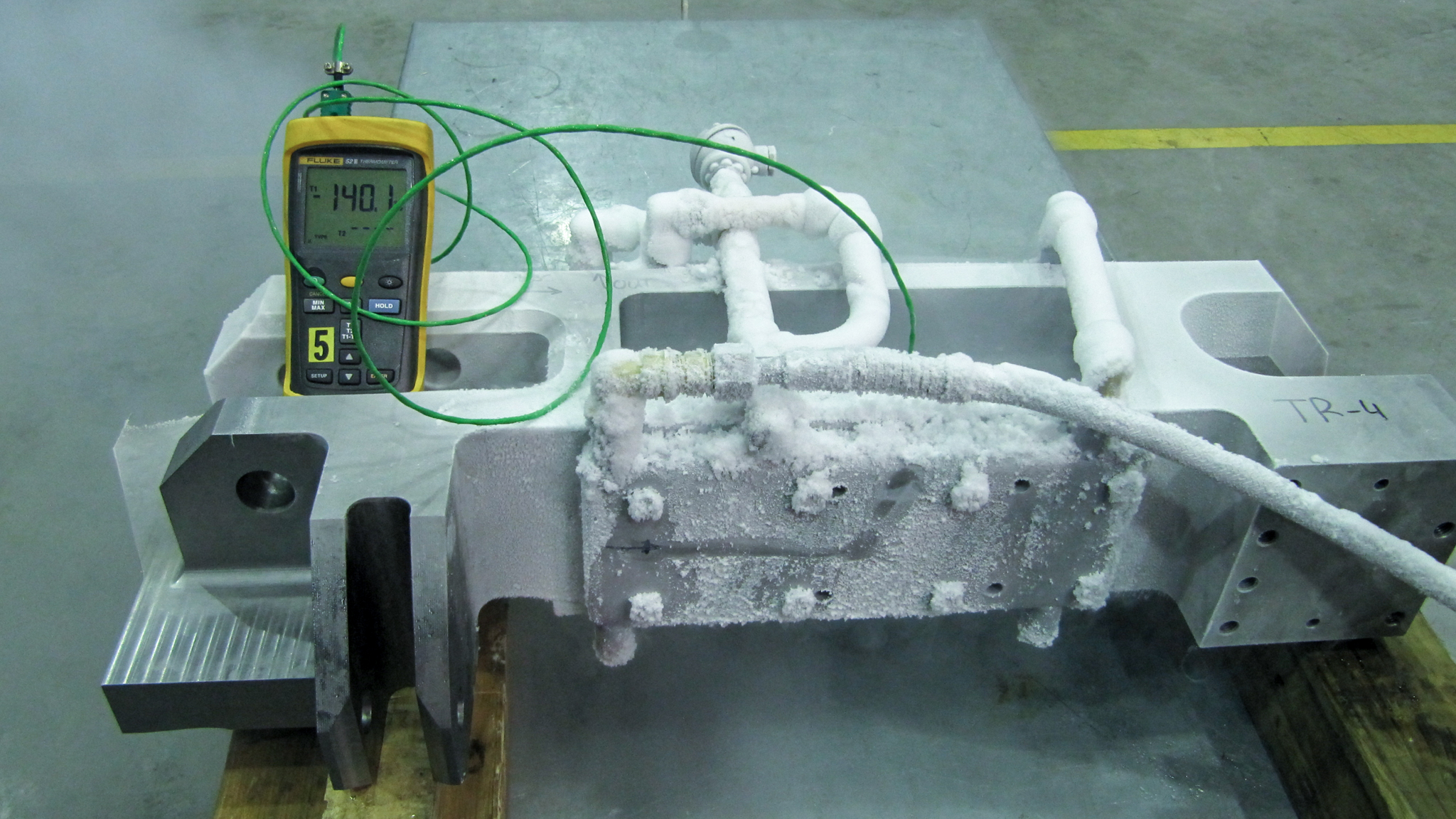

Establishing ‘material allowables’ at 20 K is crucial due to the lack of prior experience with such conditions. Testing capabilities at this temperature had to be developed from scratch. Over the past decade, NLR’s test house has developed modular and specific cooling solutions for material and structures testing, utilising various cryogenic and thermal equipment. NLR’s approach prioritises affordability, maintainability, safety, scalability and accuracy, over a broad operating temperature range.

NLR now routinely tests the static properties of various materials for several customers at 20 K, a capability shared by only a few test houses globally (if any). In the meantime, future development continues, including full-scale structure testing at 20 K and material testing at the same temperature with dynamic loading and under hydrogen conditions.

More information

read the white paper to gain further insight into the steps NLR has taken on its journey to shift from ‘cold’ to ‘cryogenic’, and even to ‘deep cryogenic’: Whitepaper ‘cold testing has become hot’.

Would you like to know more? Please also take a look at the following:

- The booklet ‘R&D more electric and hydrogen powered aerospace‘