The transport industry is making more and more use of composite materials, or composites for short. Nothing further obstructs a major breakthrough of this light and strong construction material following the sharp decrease in the costs. The latest acquisition of the National Aerospace Laboratory of the Netherlands (NLR), the fibre placement machine, has enabled Dutch industry to mass-produce large composite components at low cost.

The transport industry is making more and more use of composite materials, or composites for short. Nothing further obstructs a major breakthrough of this light and strong construction material following the sharp decrease in the costs. The latest acquisition of the National Aerospace Laboratory of the Netherlands (NLR), the fibre placement machine, has enabled Dutch industry to mass-produce large composite components at low cost.

Composite, a carbon fibre-based ‘synthetic material’, has attracted considerable interest from aircraft manufacturers since its introduction. Their interest is not surprising because the material is stronger, more durable and lighter than aluminium, the ‘traditional’ material used to make aircraft. Steep material and production costs previously prevented large-scale use of composites. But recent years have seen a drastic drop in the cost per ‘kilo’ of composite thanks to automation processes, new robotic technology and smart assembly techniques. Aircraft manufacturers are pressing ahead on using composite, with Boeing recently making a breakthrough by getting its initial orders for the ‘Dreamliner’, the first airliner made largely of composites.

Weight matters

Interest in composite is growing in all industries where weight is a key factor. ‘Economical and light’ are the twin drivers for the automotive industry when developing new models, for example. This industry, traditionally dominated by steel, has now come to the forefront in developing light and strong metal alloys. Greater familiarisation with composites has also produced a sharp increase in interest in designing composite car parts. Lamborghini has designed for its Aventador sports car a shock-absorbing chassis made entirely of composite. Over the past years the quality of composite has increased. Today it is easier to process and its production no longer requires an autoclave, a pressurised steam-heated vessel. Thermoplastics are particularly promising because they harden easier and faster. When heated they become soft again, making it easier to join parts together. Against these enhanced modelling and assembly possibilities, however, the costs remain high, especially of high-grade thermoplastics. But low-grade thermoplastics, which in simple terms are plastics that contain carbon fibres, have become a lot cheaper and their quality is now so good that they are usable for the mass production of car parts.

Greater passenger comfort

Greater passenger comfort

An aircraft made entirely of composite is something of a preoccupation. Composite is well-suited to shell structures like fuselages and wings that are exposed to high stresses in a horizontal plane. Composite is less suitable for aircraft components made of vertical layers, because the separating resin layer, the weakest link, can be pulled apart. Moreover, composite has a general disadvantage in that it is more brittle and repairs are trickier after impact. With composite it is not possible simply to add some strengthening rivets as occurs with aluminium. Nevertheless, composite has some obvious advantages: it is lighter and stiffer and exhibits less material fatigue. It is also a material that is usable to increase comfort for passengers. You can keep the cabin moister, which could cause corrosion if the same were to be done with aluminium. Composites have consigned passengers with dry eyes and airways to history. You can also increase cabin pressure without excessively stressing the fuselage. Instead of feeling like you are breathing thin air on top of a 3000-metre mountain, the mountain will feel more like 2000 metres.

New fibre placement machine

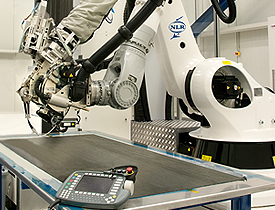

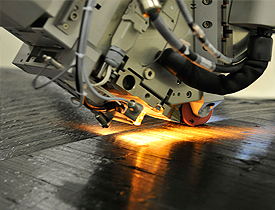

NLR is a major international player in thermoplastic research and development. Its research domain encompasses product development, machining, testing, methodology development, stressing and certification. This integrated knowledge has made NLR a highly attractive partner for the Dutch composite industry. Following in the footsteps of the aircraft industry, more and more ship, car and rocket builders are approaching NLR, including more and more companies from countries like China, Russia and Brazil as well as from the Netherlands. This interest looks likely to increase still further, because since the start of this year NLR has had a new, state-of-the-art fibre placement machine that can be used to build prototypes. What makes the machine special is its capability to process different composite materials and to make virtually any type of object, including large ones with complex shapes and a higher TRL level. Besides making prototypes, NLR uses this facility to conduct basic research. It is possible to determine accurately the production time of a certain object and the properties that the object will have. The facility will not be the last of its kind, because NLR intends to purchase a new facility controlled by robotic technology to enable the completely automatic draping, cutting, jointing and pressing of composite materials.

E nterprise, development and education

nterprise, development and education

NLR also conducts more fundamental research into composites. Among other things the organisation is studying how better to detect and repair composites damaged by impact. Additionally, NLR is working on new weight-saving plaiting techniques. These activities demonstrate NLR’s pivotal position in the latest advances in developing and using composite. NLR’s role as Dutch industry’s R&D department will be reinforced still further since the foreseen establishment of Compoworld on July 4th 2012. This is a collaborative arrangement involving industry, educational institutions and NLR. NLR offers students research and work experience placements. There are two-way benefits: students gain practical experience and, conversely, bring the latest theoretical knowledge to NLR. If they go on to start their own company, they will already be familiar with NLR and will know who to approach for know-how and advice.