Sustainability and Environment

14 March 2025

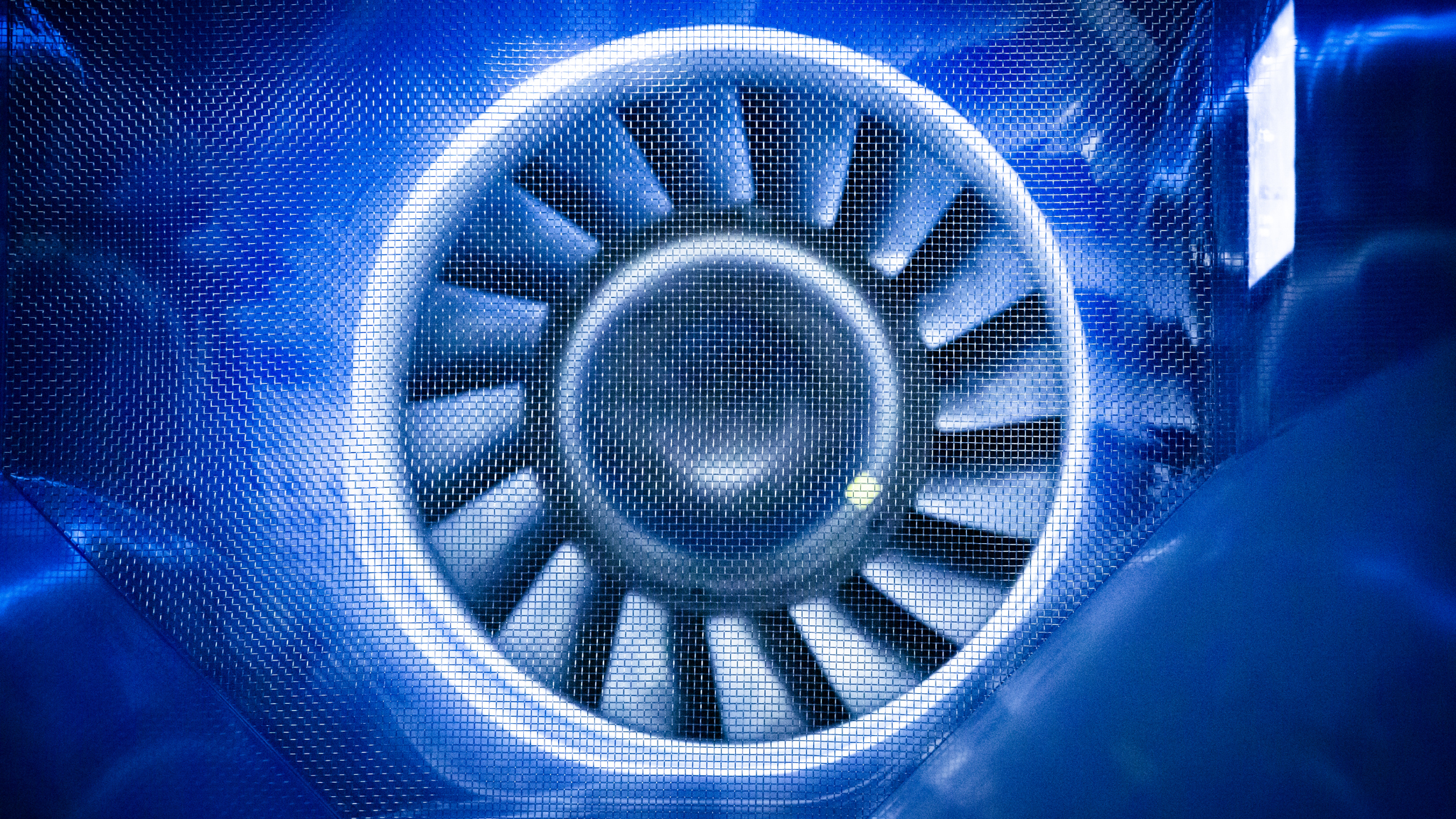

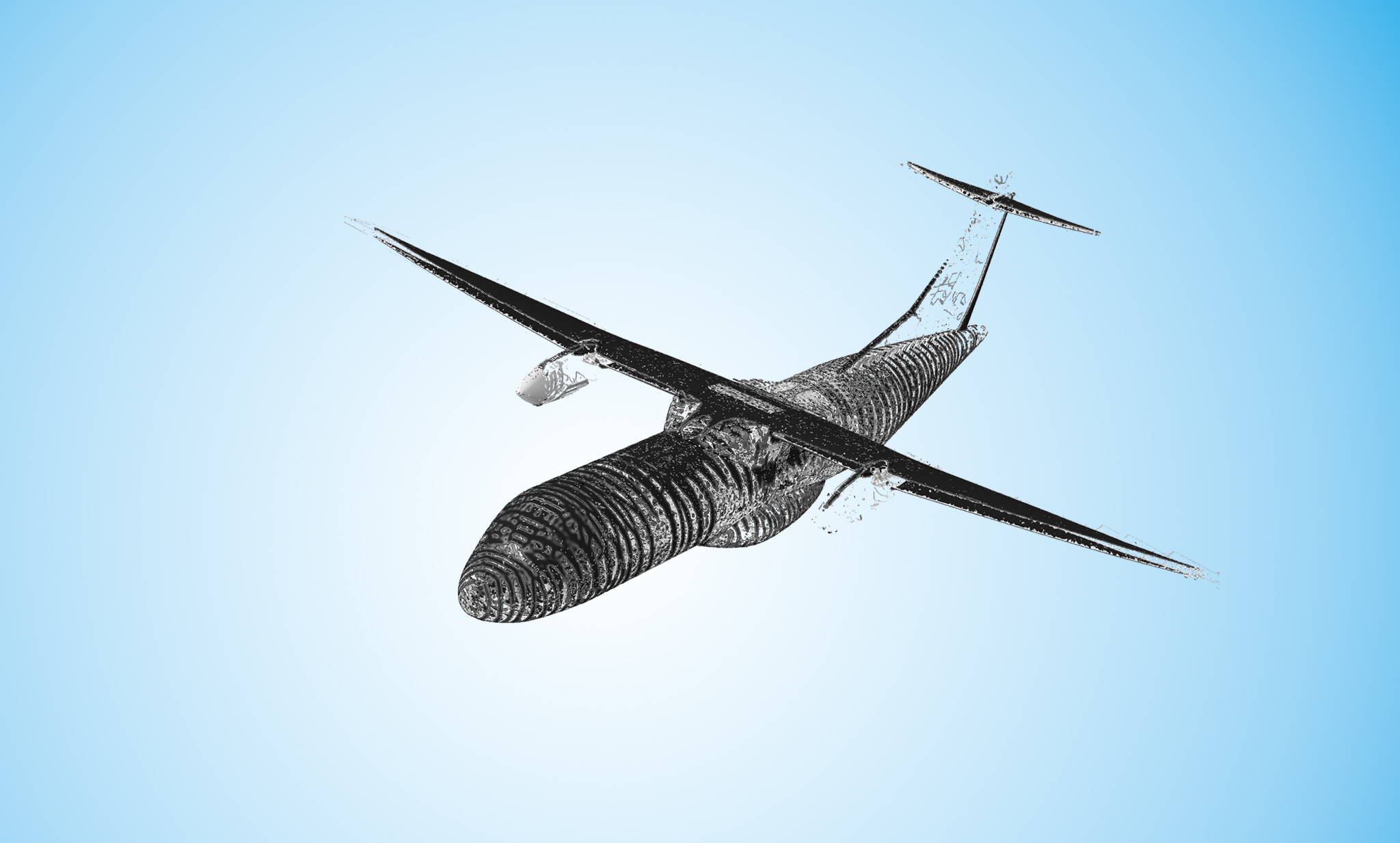

NLR and Cryoworld collaborate on flying with liquid hydrogen

NLR is taking a further step towards more sustainable flight by partnering with Cryoworld to develop a liquid hydrogen tank. This follows the agreement with zepp.solutions for a fuel cell system. The new collaboration contributes to NLR’s ambition to conduct a demonstration flight on liquid hydrogen in 2026. NLR aims to achieve manned flight on […]

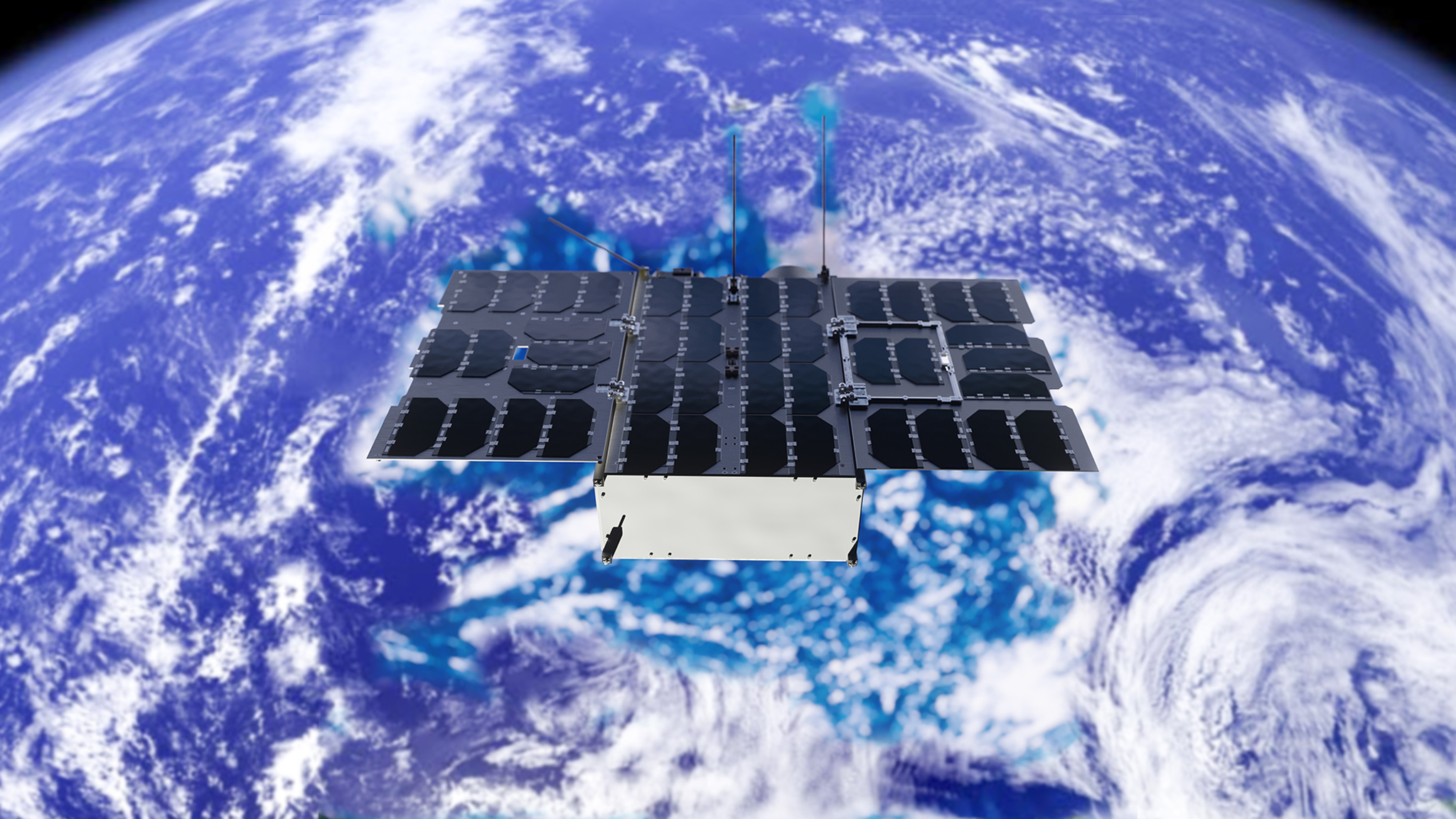

Platform System Design

22 January 2025

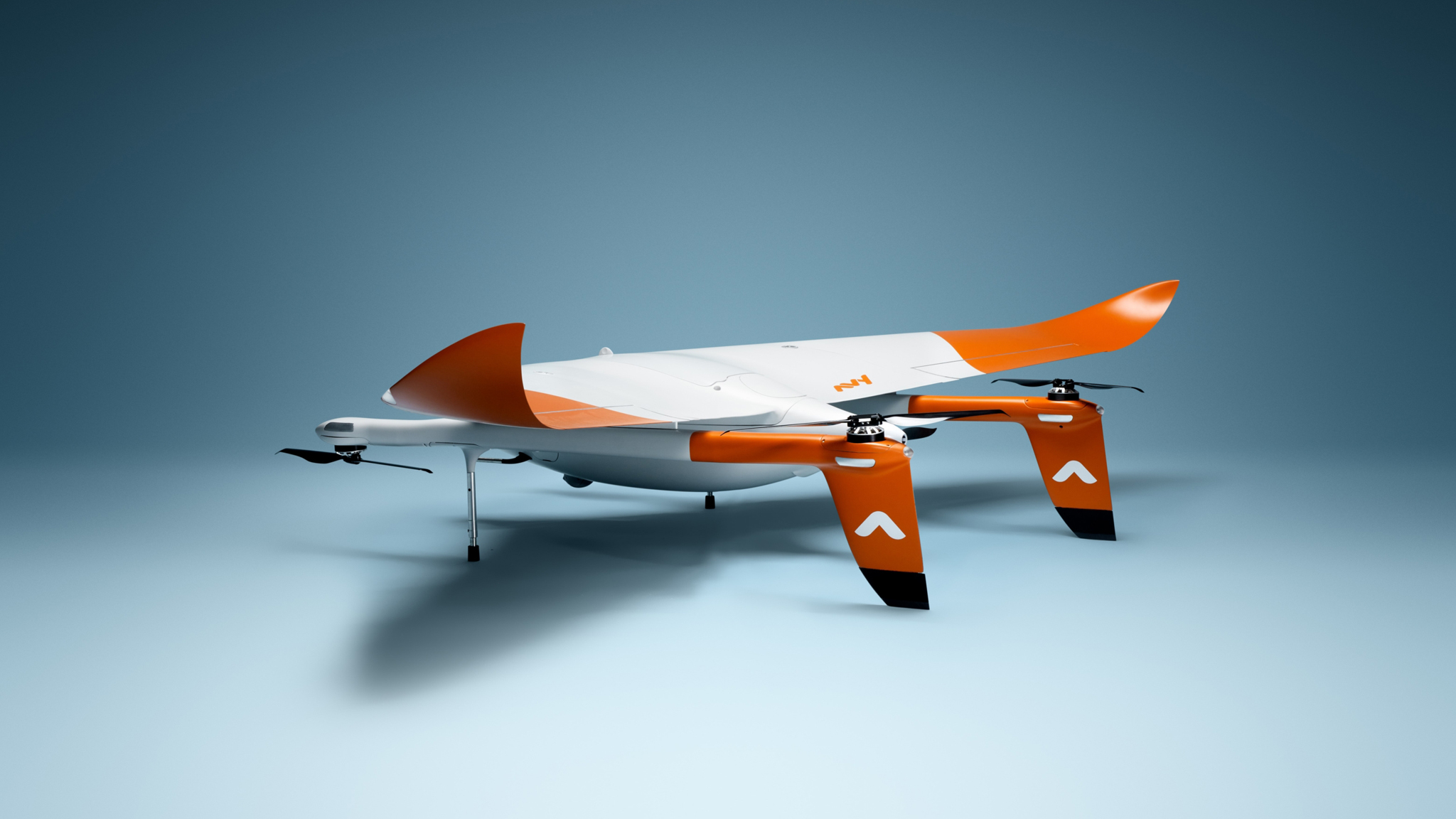

Avy and NLR partner to drive drone innovation

NLR has partnered with Avy, a Dutch company that develops autonomous fixed-wing drones tailored for humanitarian, health, and environmental missions, with a focus on creating a sustainable impact. NLR has acquired an Avy drone for testing and evaluation, aiming to drive innovation in aerospace applications. This collaboration supports the development of sustainable and cutting-edge drone […]

News updates

News updates

AGENDA

Let’s meet!

9-12 Apr

AERO Friedrichshafen

13-15 May

Airspace World

16-22 Jun

Paris Airshow

5 Oct

ESA/ESTEC Open day

6-7 Oct

SAMPE Europe

8-9 Oct

Electric & Hybrid

14-16 Oct

MRO Europe

18-20 Nov

Space Tech Europe

Areas of expertise

Programmes

Markets

NLR Repository

Newsroom

Stay up to date with the latest developments. In the Newsroom you can find the latest news, articles, and blogs from NLR. We also showcase a range of videos and publications here. For more video content, please visit our YouTube channel, NLRmedia.