The design and optimisation of engine nacelle and exhaust acoustic lining materials is crucial for reducing noise pollution and improving overall engine performance. However, verifying the effectiveness of these materials can be a complex task. NLR can assist in the design and experimental verification of engine nacelle and exhaust acoustic lining materials, as well as provide a quick comparison of the damping characteristics of various acoustic liner panels. Additionally, we can help validate the effects of grazing flow on the acoustic impedance, ensuring that your engine liner design meets the required standards and performs optimally.

NLR can support you with:

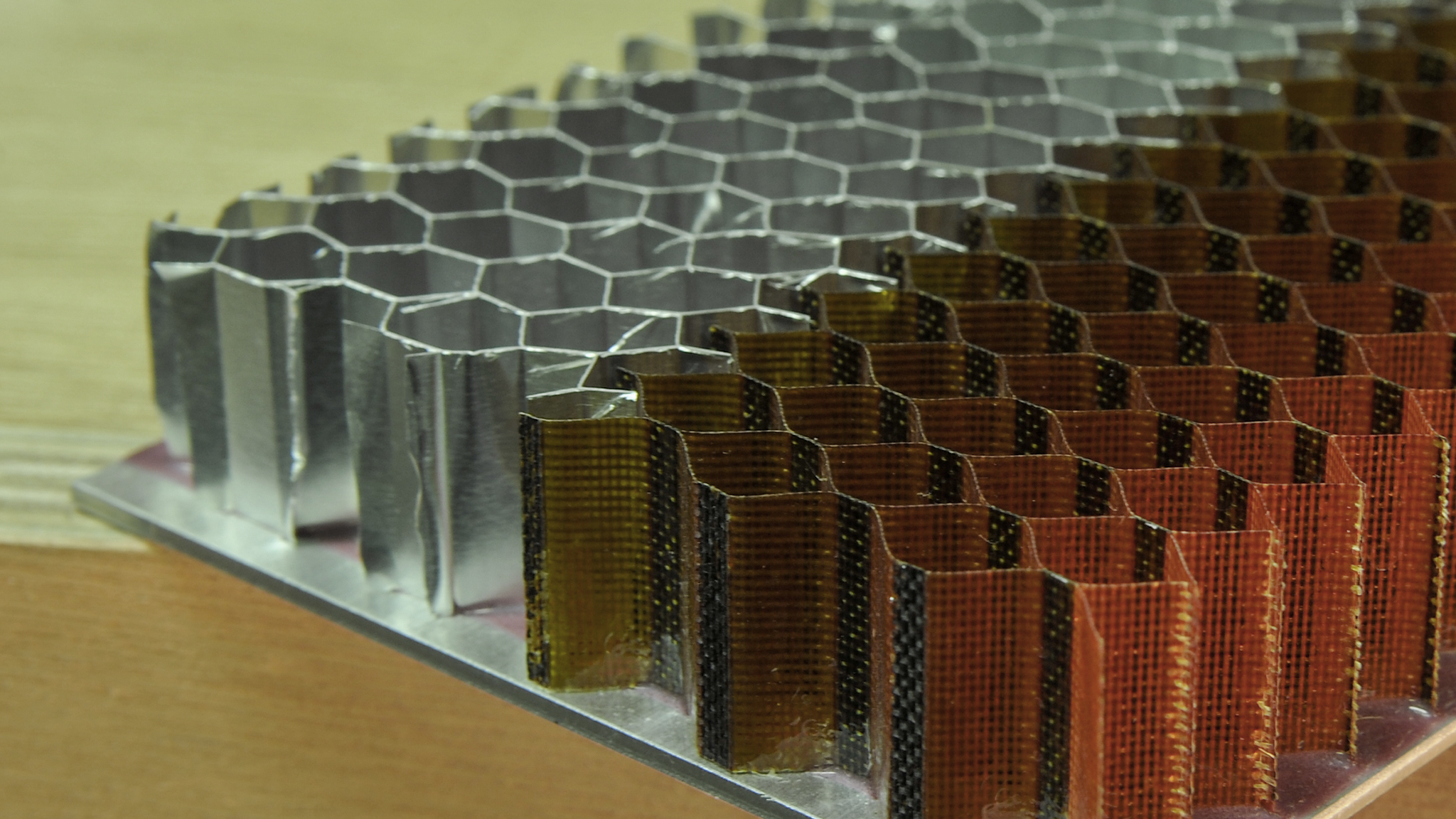

- Acoustic and flow field measurements on wall mounted sound absorbing materials (liner samples) for engine air intake and exhaust systems using the NLR-Acoustic Flow Duct Facility (FDF)

- Development of accurate simulation tools to predict acoustic waves of hot gases in variable diameter exhaust systems with acoustic lining

- Optimisation of acoustic damping in engine air intake and exhaust systems

- Structural design, aerodynamics, aeroacoustics, and thermodynamics expertise for the development of advanced engine systems

- Utilising our state-of-the-art FDF facility with capabilities including: a test section of 0.30 x 0.15 m2, a maximum flow speed of Mach 0.8, a maximum sound pressure level (SPL) of 155 dB for in-situ impedance measurements and an overall sound pressure level (OASPL) of more than 130 dB for insertion loss measurements.