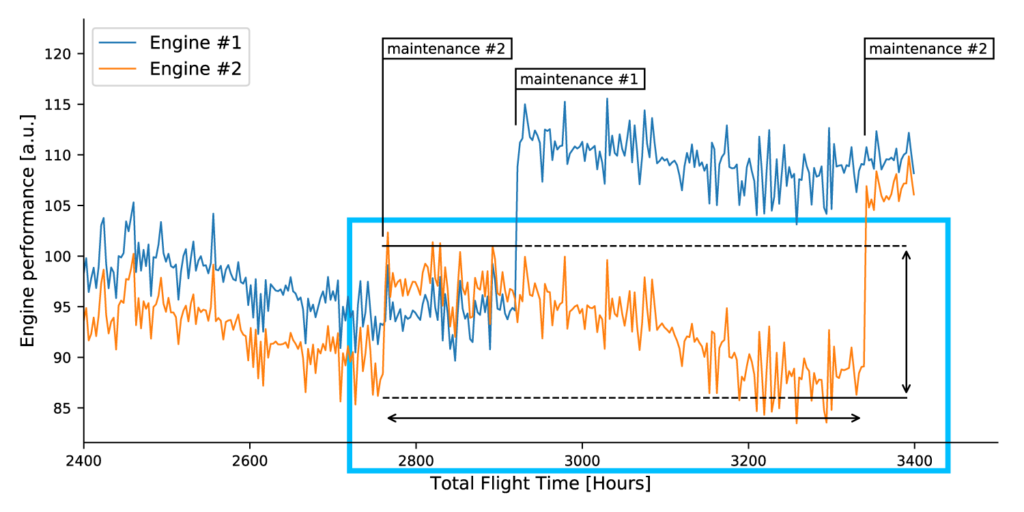

An important trend in the sustainment of aircraft engines is the transition from preventive maintenance to predictive maintenance. This concept aims to minimise the engine down-time and maintenance costs while preserving its required performance level and airworthiness. For this it is necessary that the momentary engine condition can be established and that this condition can be reliably extrapolated to a convenient moment in the future in order to facilitate the planning process.

The challenge

Legacy aircraft engines only feature a rudimentary form of health monitoring, which makes it hard to establish and extrapolate their condition without intrusive and time consuming post-flight inspections.

The solution

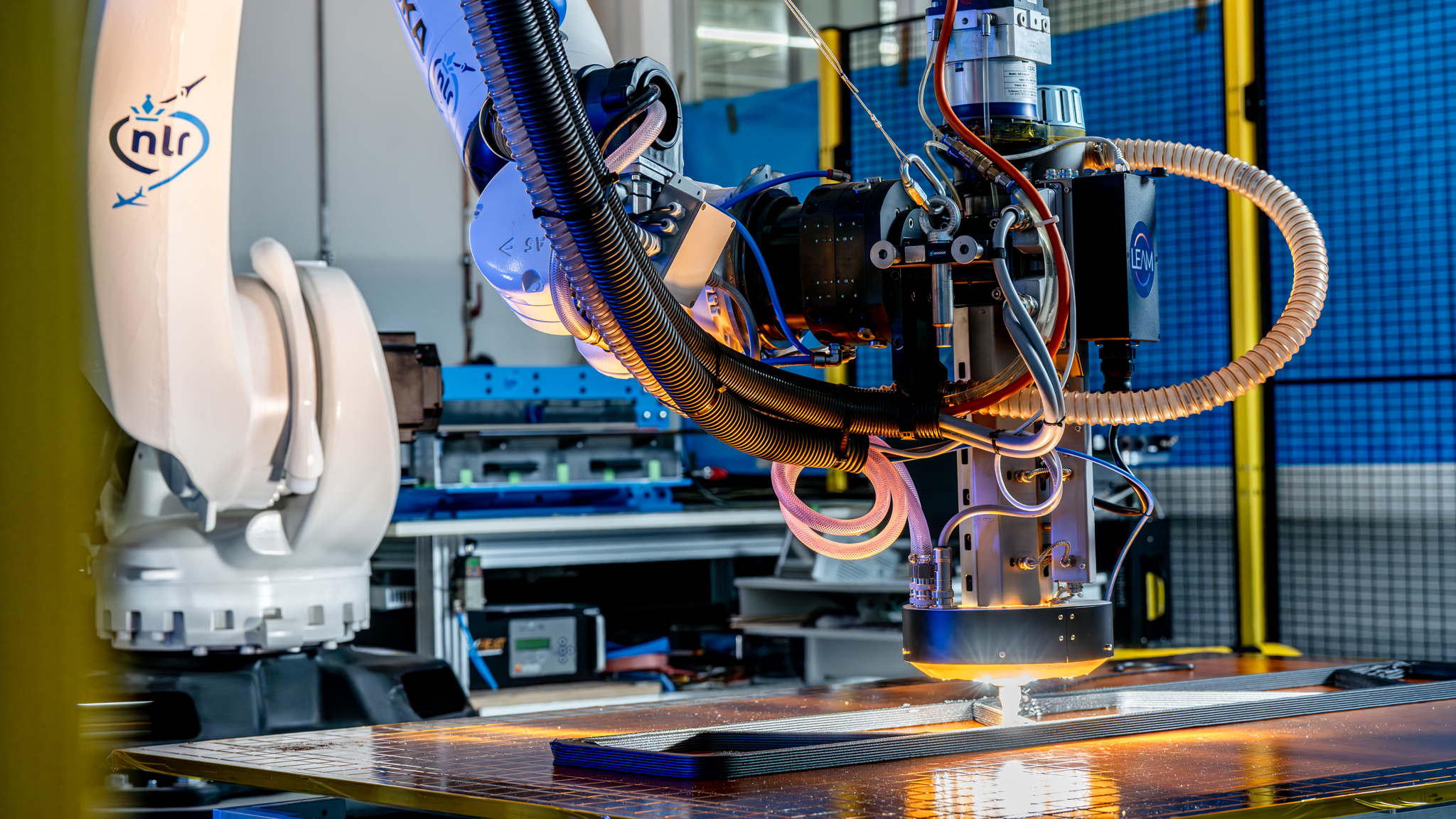

NLR developed an alternative and simple approach, Engine Conditioned Trend Monitoring, to establish the current and future engine condition from the limited data that is available from the digital engine control unit (DECU) which is present on many legacy aircraft engines.

What did we do?

For a particular turboshaft engine that is used on a military helicopter we have developed a data-driven approach to empirically derive a measure for the overall engine condition from a handful of sensor data, viz. the engine torque, the power turbine inlet temperature, the air speed, the outside air temperature and the pressure altitude.

We were able to identify engine degradation over time and correlate it to specific usage patterns and maintenance actions. This enabled the operator of the helicopter to perform predictive maintenance based on the operational theatre and usage of the helicopter. The model has been verified against historical data (known engine failures).

Project partners:

Royal NLR and Royal Netherlands Air Force