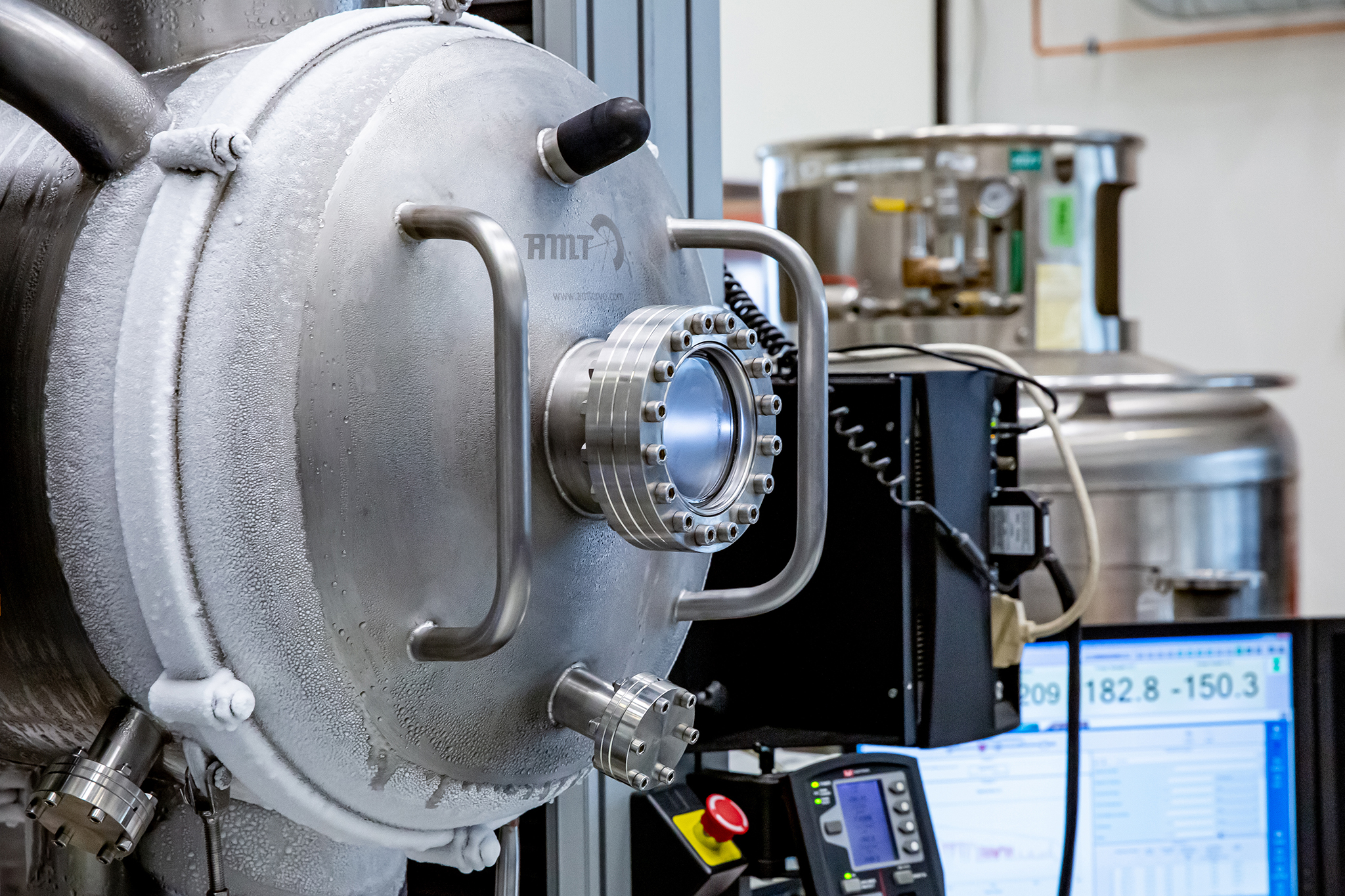

NLR acts as a one-stop-shop for “Non-Standard” testing of aircraft parts, structures and materials. The traditional structural testing has evolved, it includes energy transition related testing: deep cryogenic, hydrogen, fuel cells, and hydrogen electric power trains (in full or its components).

We have the capability to offer you inspection, testing, characterisation and failure analysis. For structures, we can do that on material level, coupon level, component level or full-scale level. We can perform standardized tests, material qualification, certification tests, or tests made fit for your purposes.

Energy transition related testing includes; mechanical testing to enable usage of liquid hydrogen (mechanical properties @20K, permeability) and energy related testing to enable the usage of hydrogen electric power trains (electrical performance, energy (heat) management, EMI, fuel cell health monitoring).

We can assist you in designing, manufacturing and machining your test articles and test setups and help you to set up a test plan. Our simulation, engineering, manufacturing and machining capabilities enable us to provide you with the best tooling and test setup structures. This document gives an overview of

available testing equipment, including its specifications.