Construction and Manufacturing

27 February 2025

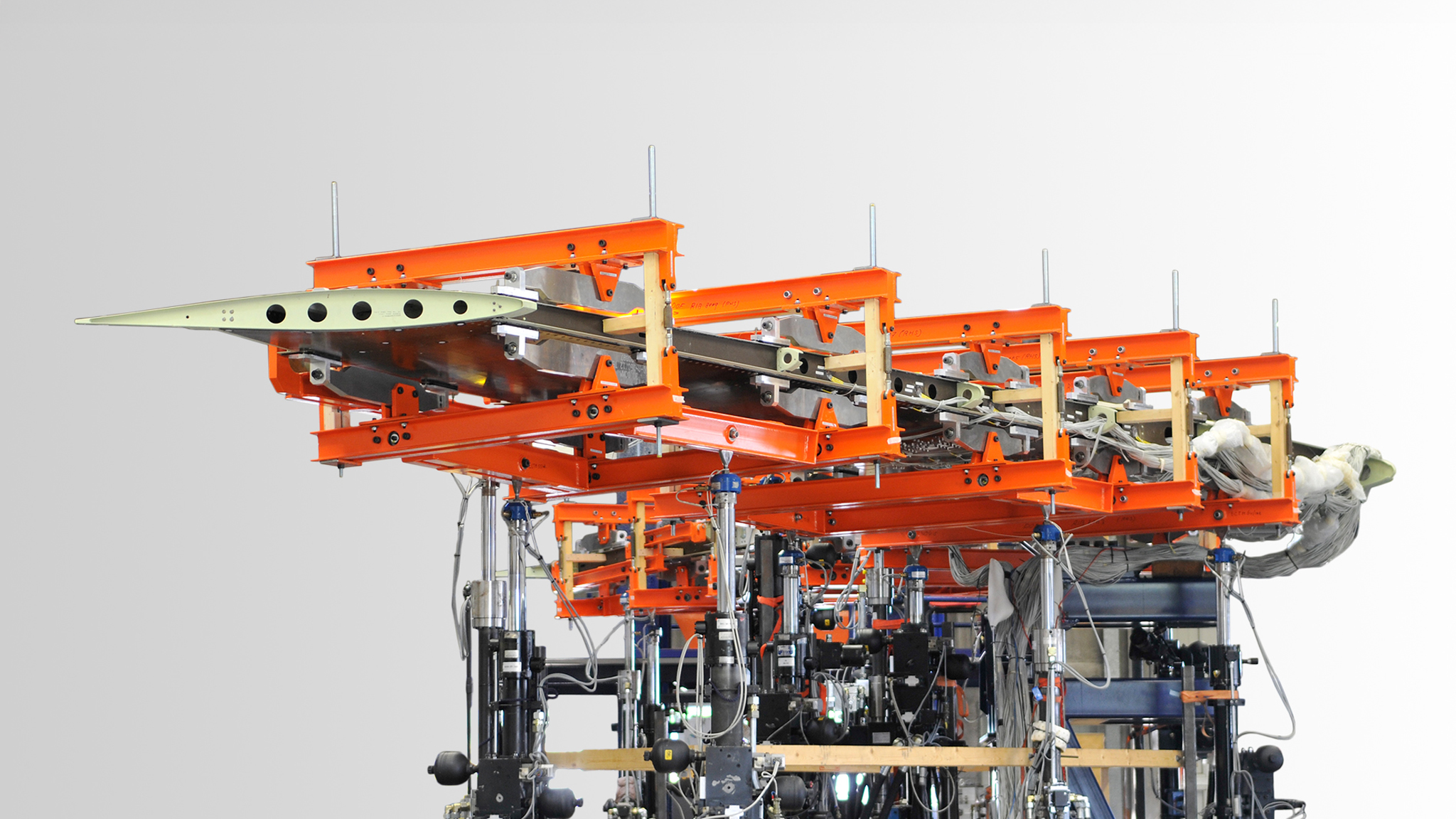

Full scale testing – certification testing

NLR offers comprehensive testing capabilities for components and full-scale structures, providing support throughout the entire testing process. Our expertise includes setting up tailored test plans that meet specific requirements, as well as ensuring that tests are certification-ready when necessary. We can advice you on finite element modelling and damage tolerance, and assist with processing, interpreting, and correlating test results. Over the years we have built a track record on the (certification) testing of full-scale structures and components for various aircrafts and helicopters. We are used to work both in a research environment and according to a certification and conformity regime.

27 February 2025

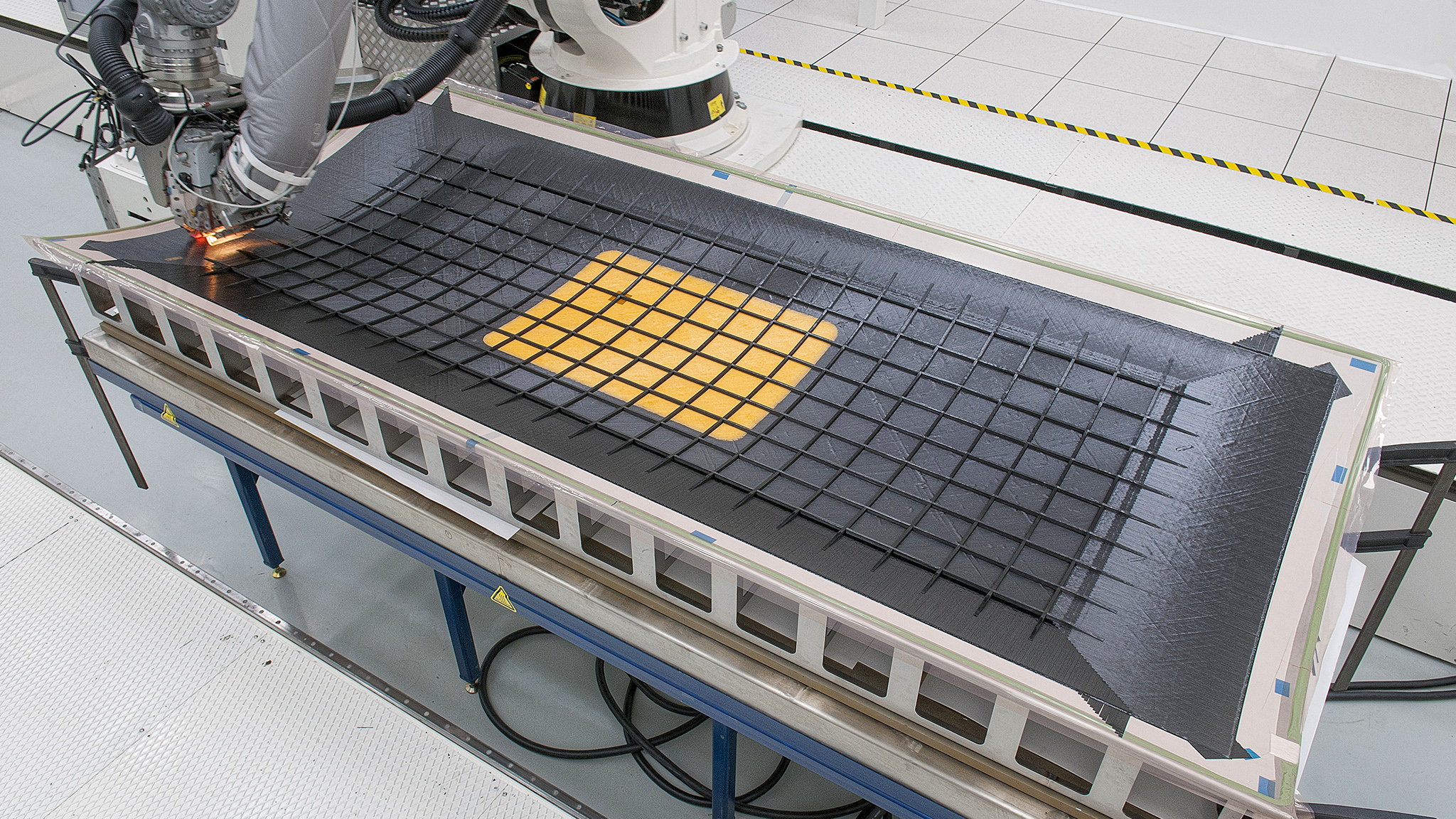

Structurally integrated antennas

Our team provides expertise in antenna design and qualification, with a focus on structurally integrated antenna solutions for aircraft antennas. We possess in-depth knowledge of broadband phased array antennas, including beam steering capabilities, as well as smart arrays for mitigating interference and addressing antenna aperture deformations. Additionally, we offer radome modelling and analysis, utilising computational tools to predict antenna performance on aircraft and satellites, and have measurement capabilities for antennas and radomes.

26 February 2025

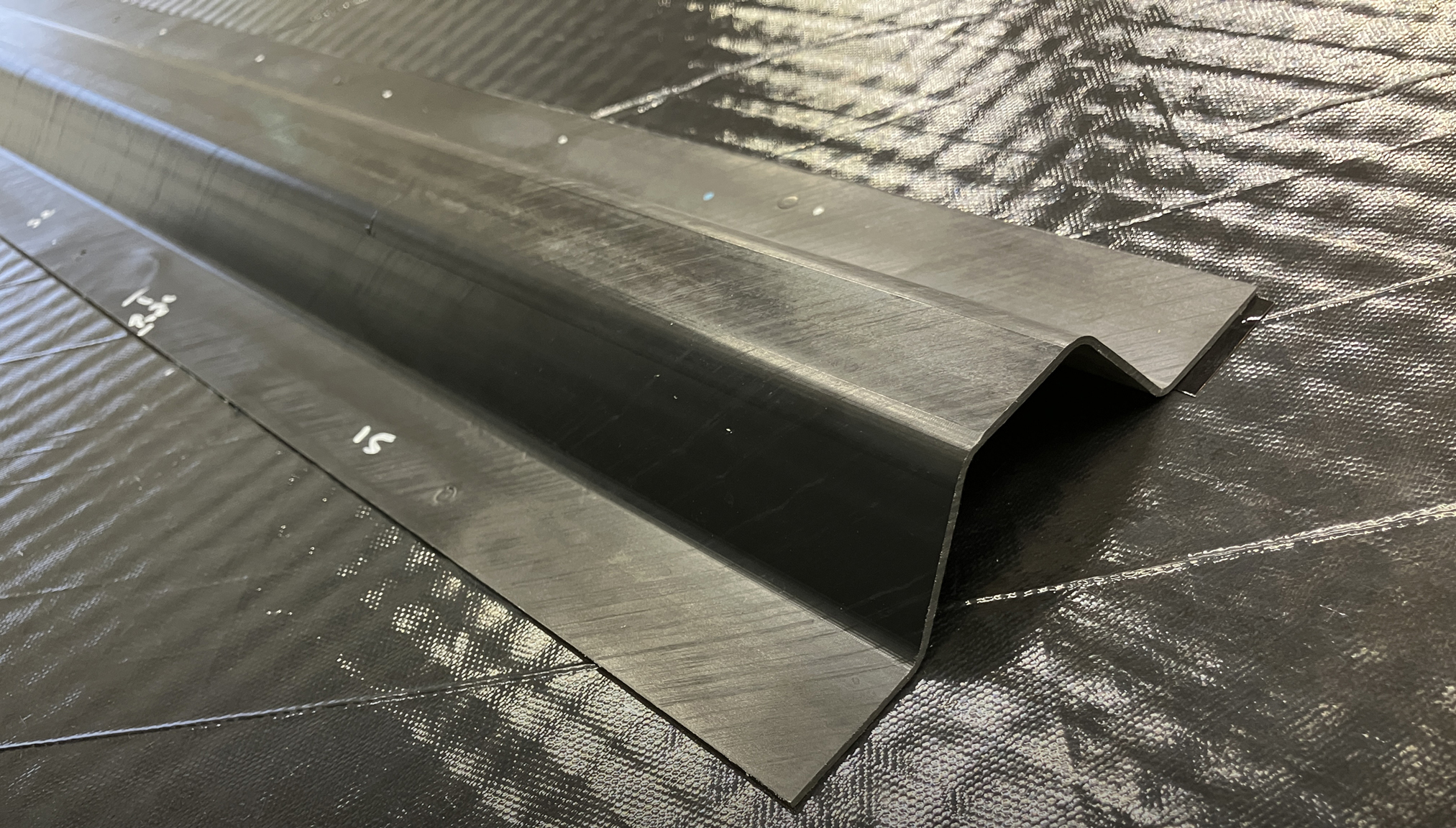

Wind tunnel models

NLR delivers and develops wind tunnel models with a range of sophisticated features, including local force and moment balances, air-driven jet engine simulators, air-driven propellers in metal or composite, remote controls for angular adjustment of control surfaces for low or high speed, as well as remote controls for special components like parachutes, refueling hoses, and drogues. Our models can also be equipped with rapid prototyping parts, six-component rotational balances, and extensive arrays of static pressure taps and dynamic pressure transducers.

26 February 2025

Wind tunnel equipment

NLR has extensive experience with unique products and is accustomed to prototyping and perfecting custom-engineered devices. Our expertise includes designing and manufacturing specialised devices and tools for wind tunnels, model integration, and enhancement. We have experience in developing remote controls for control surfaces of wind tunnel models, model stings and adapters (also instrumented with strain gauges), test rig support for air-powered propellers including pressure piping, pressure rakes, and six-component balances (also for cryogenic applications). Our expertise extends to designing and manufacturing specialised wind tunnel parts and instrumentation. NLR can help you get the most out of your test by designing, manufacturing, and instrumenting specialised wind tunnel equipment. Support is available from the early beginning of the project until commissioning and beyond.

25 February 2025

Balance design and manufacturing

NLR has over 50 years of experience in the design and manufacture of wind tunnel balances and related wind tunnel equipment. NLR designs and manufactures wind tunnel main balances (internal or external) for operation under various conditions (pressurized, cryogenic). Parameter optimisation routines can be incorporated in the design process by means of finite element methods.

25 February 2025

Impact on structures

NLR has extensive capabilities to model and simulate various types of impact events, including low and high-velocity impacts, and assess their consequences on damaged structures. Our expertise includes specific knowledge of impact on thick composite components. We also have in-house models for drones and a validated bird impact model, allowing us to predict damage initiation and propagation in different materials and aircraft structures, including metals and composites.

25 February 2025

Digital twins

Royal NLR has experience in developing several types of Digital Twins, with partners in the aerospace components manufacturing industry, the Dutch MoD, and aircraft OEMs. To support these activities NLR leverages the availability of research facilities such as the ACM3 Smart Industry Field Lab, several fixed and rotary wings, as well as the RC glider, and unmanned research platforms. We also have a Pipistrel Velis Electro as Digital Twin platform at our disposal, equipped with relevant structural sensors and (flight) data acquisition equipment.

25 February 2025

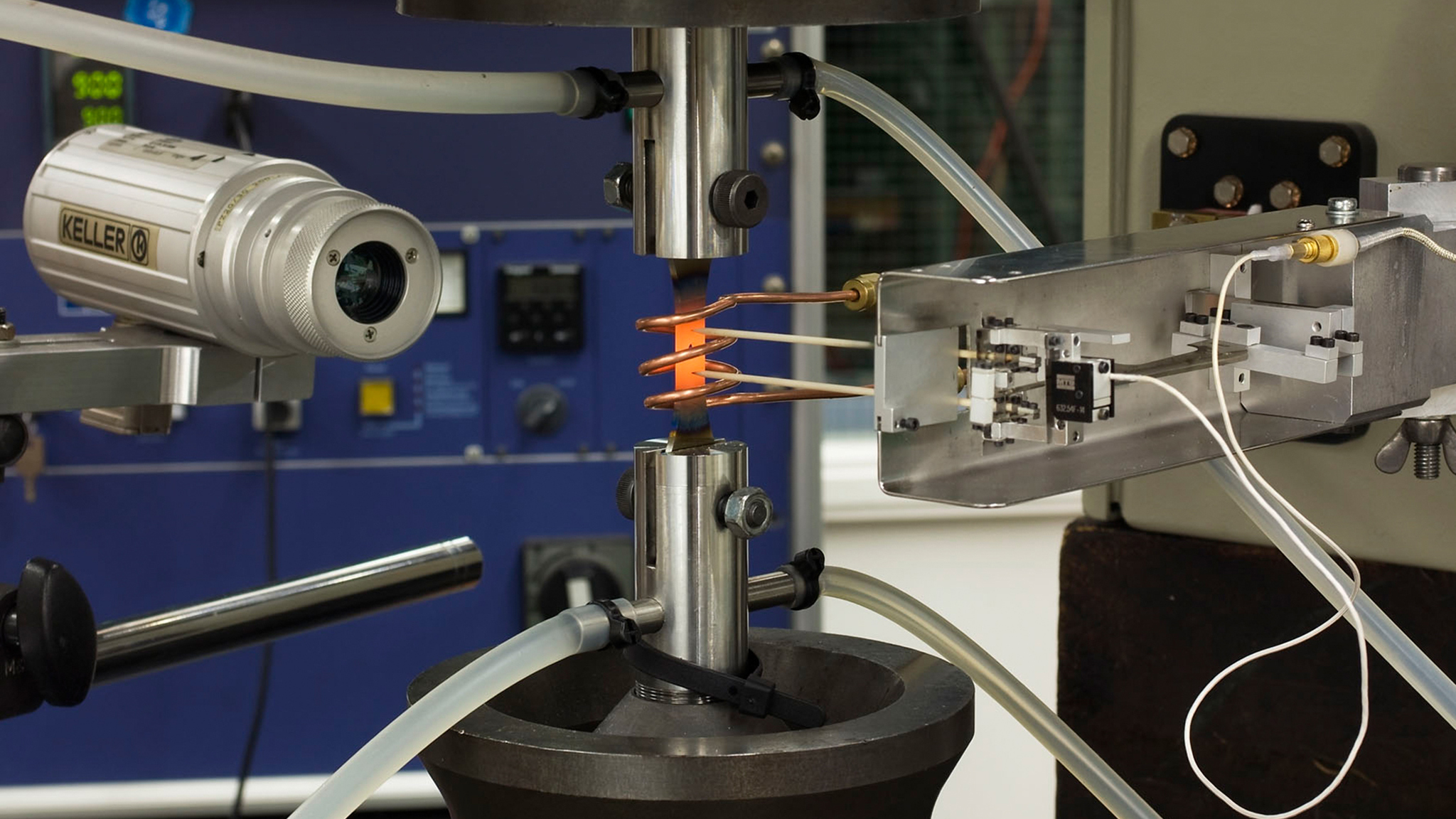

Coupon testing – materials testing

The NLR research infrastructure encompass a wide variety of coupon and materials testing, including inspection and calibration systems, ranging from creep and quasi-static to dynamic and high-frequency testing. We mimic aerospace, space and off-shore environments, civil and military, in order to conduct realistic testing. Our testing services include static, fatigue, and damage tolerance testing, all of which are performed in accordance with international standards or tailored to meet specific client requirements. Additionally, we execute material evaluation and qualification programmes.

We can accommodate a wide range of environmental conditions to meet your specific testing needs, including ambient, low (-55°C), cryogenic (-180°C), elevated (80°C), and high-temperature (1250°C) environments, as well as controlled humidity, corrosion, and saturation conditions.