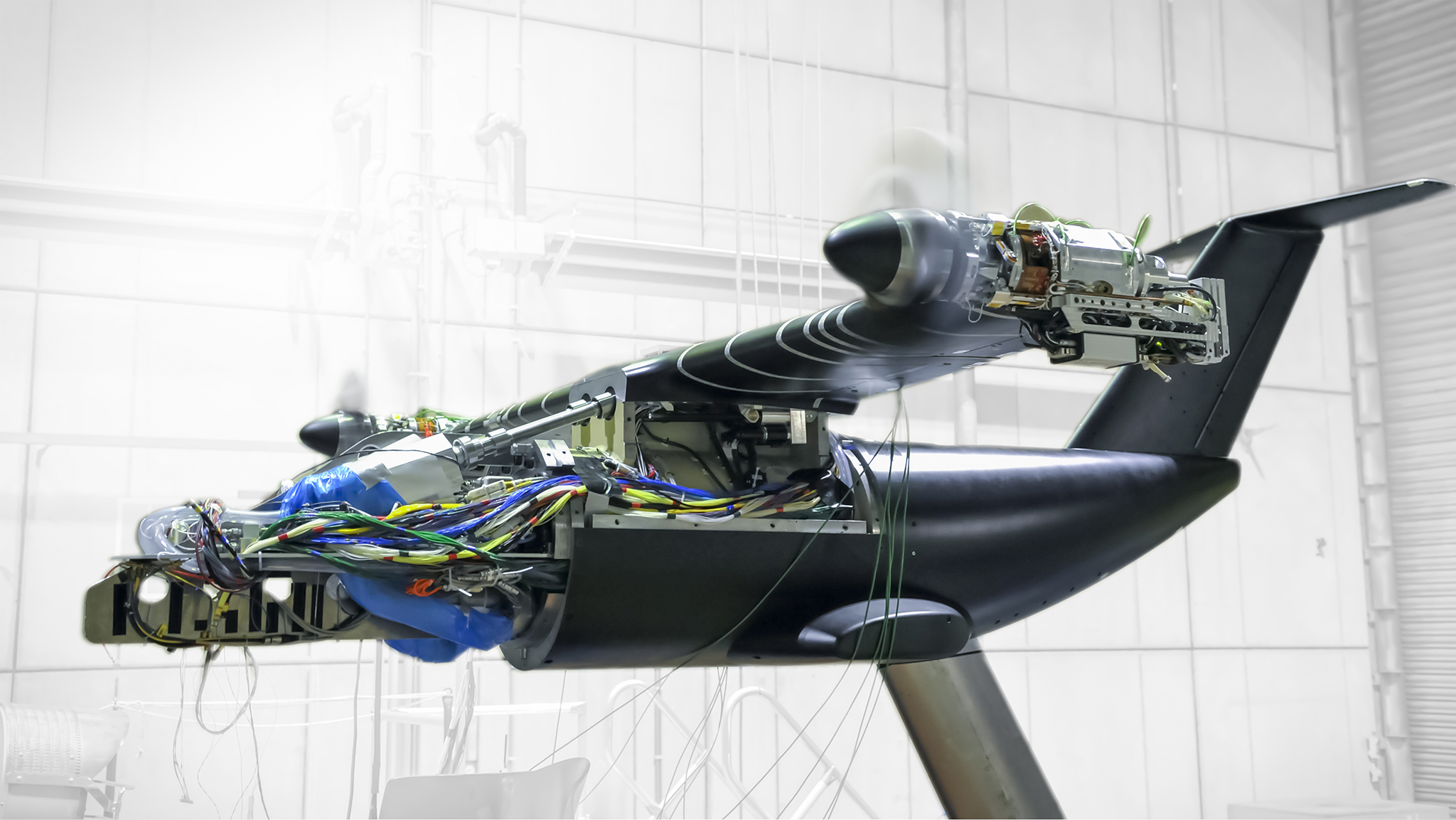

Our wind tunnel models are engineered to be highly advanced and instrumented with cutting-edge sensor systems, enabling testing in a wide range of environments, including subsonic, transonic, ambient, cryogenic, and icing conditions. These models feature advanced smart technologies, including remote controls, rotating systems, and turbine-powered simulators, as well as sophisticated components such as carbon composite blades and precision instrumentation. With the added capability of telemetry systems, balances, and pressure rakes, these models provide unparalleled data acquisition and analysis capabilities.

NLR boasts a legacy of over 50 years in wind tunnel balance design and manufacturing, with a proven track record of delivering high-quality solutions for wind tunnels globally. Our extensive experience with various types of wind tunnel models and wind tunnels worldwide has given us a deep understanding of the importance of creating efficient and cost-effective wind tunnel models that meet the specific needs of our clients. We deliver smart wind tunnel models with unparalleled functionality, designed to minimise wind tunnel occupation time and optimise test data acquisition.

Main features

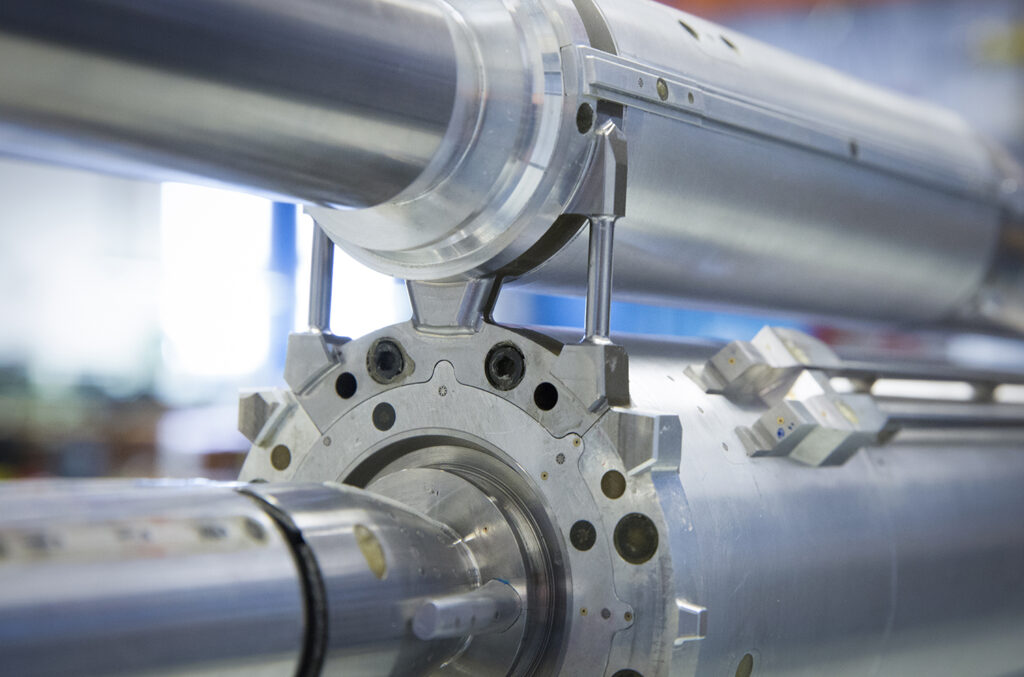

NLR designs and manufactures wind tunnel main balances for internal or external use, operating under various conditions, including pressurized and cryogenic environments. Our design process uses Finite Element Methods to optimise performance and ensure exceptional accuracy.

NLR also offers force measurement solutions to enhance the functionality of your smart wind tunnel model. We develop integrated force measurement solutions for control surfaces and complete six-component rotating shaft balances for propeller force measurements. Our rotating shaft balances can be equipped with onboard electronics for signal conditioning or data acquisition, as well as contactless data transfer via telemetry systems.

We deliver smart models containing:

- Local force and moment balances

- Air driven jet engine simulators

- Air driven propellers in metal or composite

- Remote controls for (angular) adjustment of control surfaces, for low or high speed

- Remote controls for specials like parachutes, refueling hose and drogues

- Rapid prototyping parts to create parts with internal structures such as pressure tubing

- Six component rotational balances including telemetry systems for data and power transmission from rotating to static domain

- Implementation of extensive amounts of static pressure taps and/or dynamic pressure transducers