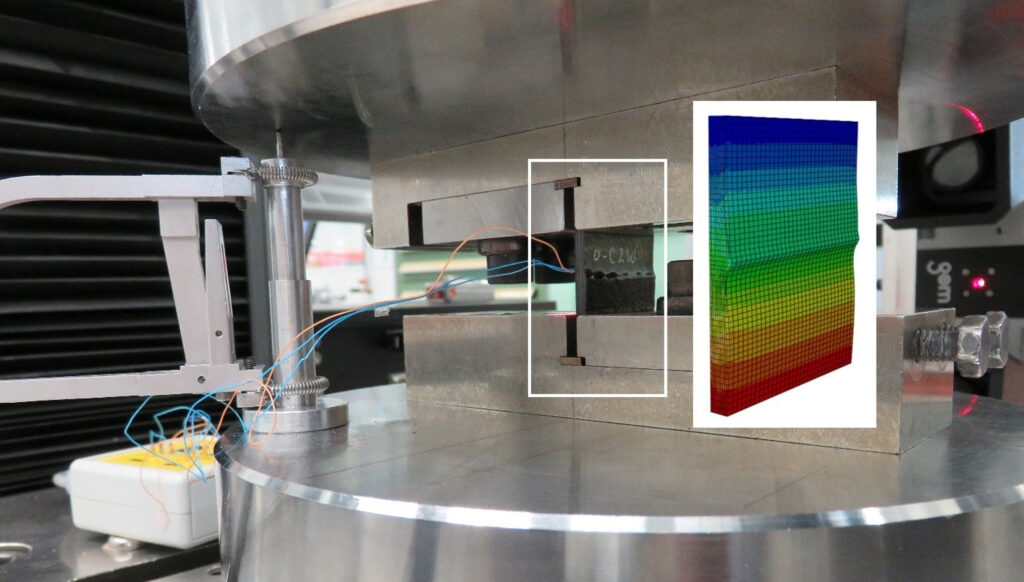

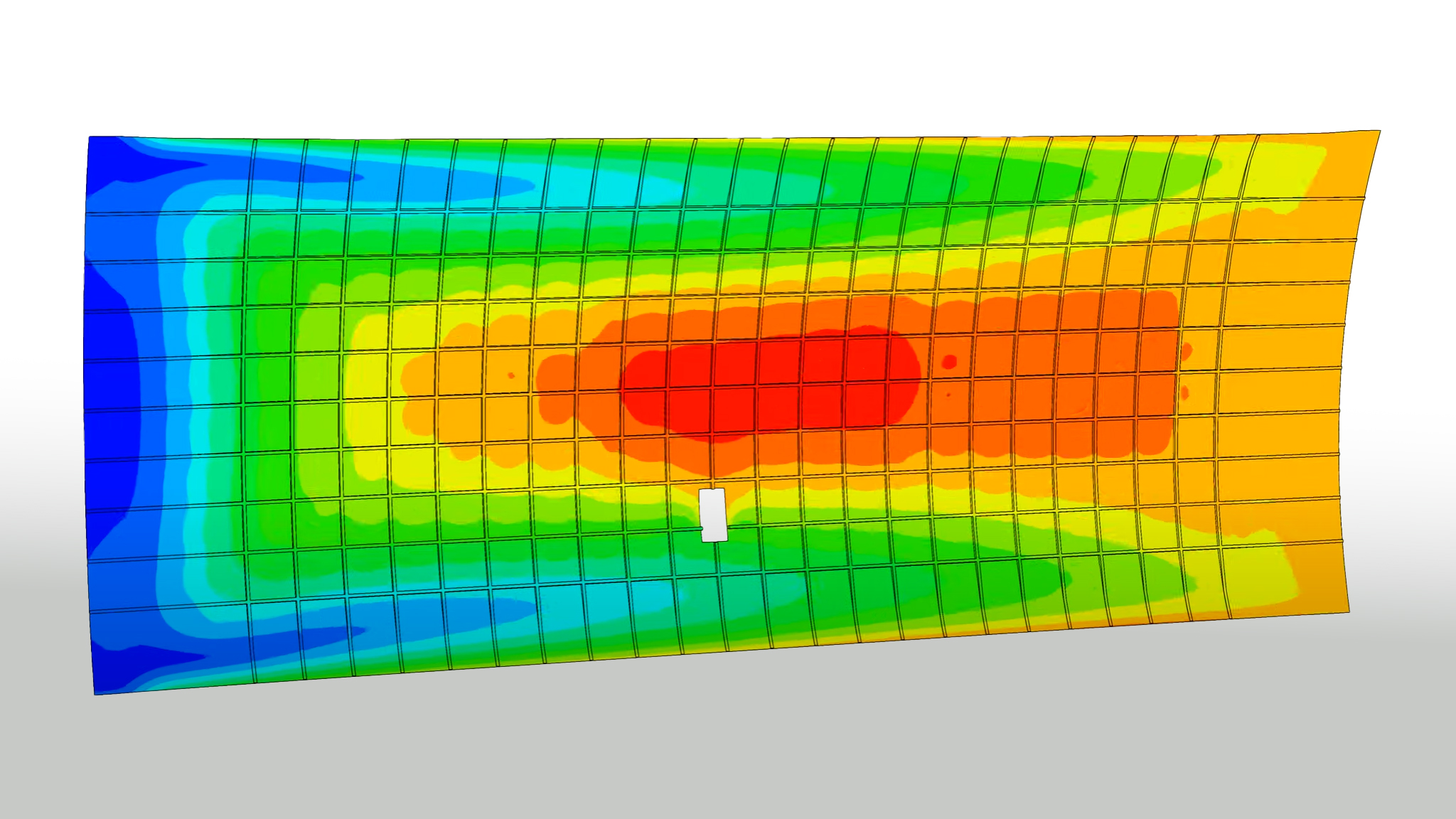

Virtual testing methods can be employed to reduce time, costs and risks associated with physical testing. This approach involves utilising modelling capabilities for metal and composite test articles in their test setup, allowing for the simulation of various testing scenarios before and during physical testing. By leveraging knowledge of testing procedures, analytical, numerical and experimental methods, the effects of defects, such as fibre waviness, on composite materials can be investigated. Furthermore, Non-Destructive Inspection (NDI) methods can be used to inspect test articles for manufacturing defects, providing valuable input for virtual testing. Additionally, optical 3D deformation measurement during physical tests enables correlation with virtual tests, fostering a collaborative environment for simulation, manufacturing and testing teams.

NLR can support you with:

- Alternatives such as virtual tests for costly physical test campaigns

- Simulating your test article in its test setup with realistic boundary conditions and loads

- Reduced order modelling to predict test article behaviour before and during physical testing

- Servo-hydraulic actuator modelling to predict actuator forces and oil flow before and during physical testing

- Evaluating the influence of a manufacturing defect on the performance of your part

- Evaluating the influence of variations in the test setup on the test results

- The certification of your component

Documents