NLR can help you measure and monitor the behaviour of your structures and components by instrumenting them on-site or in our facilities, allowing us to capture a wide range of parameters such as strains, forces, crack growth, deformation, displacement, vibration, geometry, impacts, temperature, (residual) stresses and stress distribution. We use a broad range of advanced surfacemounted-, integrated- or contactless- sensors to provide you with accurate and reliable data. This enables you to make informed decisions about your structures and components.

NLR can support you with:

The capability of performing experimental stress analysis by:

- Verifying numerical and analytical models and calculations

- Measuring stress concentrations and stress intensity factors

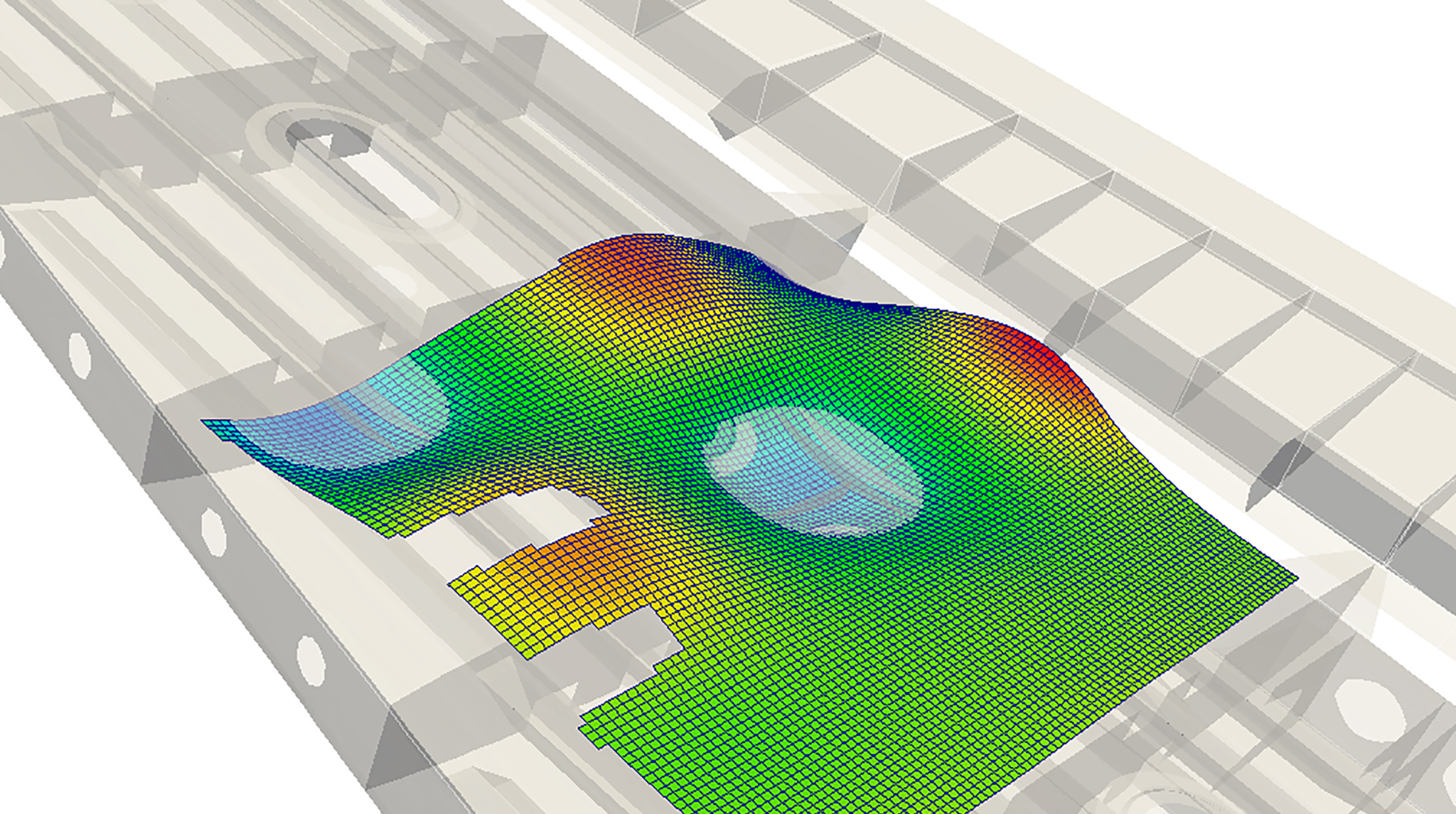

- Visualization of strain gradients and hot spots

- Visualization of crack growth, crack tip opening and local/global strain fields/distribution

- Complex motion tracking and analysis

- Tracking damage in (composite) materials

- Ground based vibration testing for Modal Analysis

- Mode shapes and relative motion analysis

- Verification and iteration of Finite Element Models

- Verification of failure behaviour

- Investigation of fracture mechanics

Moreover we have the expertise to perform:

- Strain-calibration set-up for (airplane) structures

- Instrumentation and performance measurements (also on-site)

- For static or dynamically loaded specimens, components and structures

- 3D geometry inspection with 3D scanners and photogrammetryAt roomtemperature but also at cryogen (-180°C) or very high temperatures (+1600°C)

- (Wireless) Sensor technology application for Structural Health Monitoring