NLR offers comprehensive expertise in designing, testing, and manufacturing innovative space structures, including satellite backbones, instrument platforms, and launcher components. From design verification and prototype manufacturing to inspection, environmental testing, and integration of functions such as thermal management and antennas, NLR’s capabilities also extend to smart structures, enabling the creation of lightweight, high-performance space systems.

NLR can support you with:

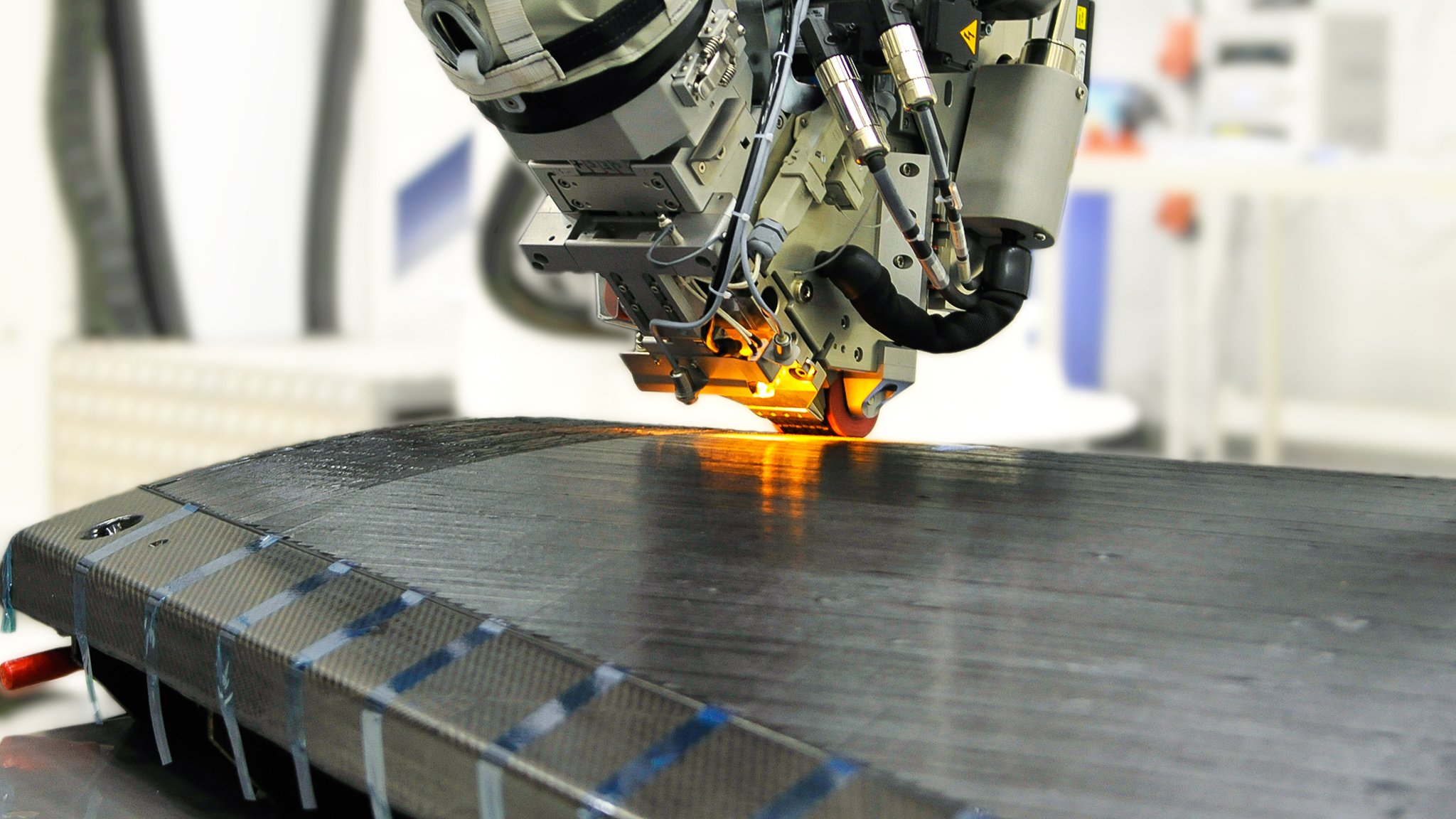

- The entire development chain for low-weight space structures, from concept to validation. This involves carbon fibre composite technology (thermoset and thermoplastic materials) and metal additive manufacturing (3D printing).

- Design concepts in composite.

- Detailed Finite Element Method (FEM) calculations for composite designs.

- Composite structure manufacturing.

- Mould design and manufacturing.

- Automated Fibre Placement.

- Resin Transfer Moulding.

- Advanced CFD and CAA (Computational AeroAcoustics) calculations.

- A wide variety of Environmental testing facilities for mechanical, climatic, electric, radiation and acoustics testing.

- Capabilities for the integration of functions in structures such as thermal functions or antennas.

- Capabilities for smart structures development.

- Capabilities for Improved Fracture Mechanics & Fatigue Crack Growth.

- Capabilities for design and manufacture of launcher wind tunnel models.