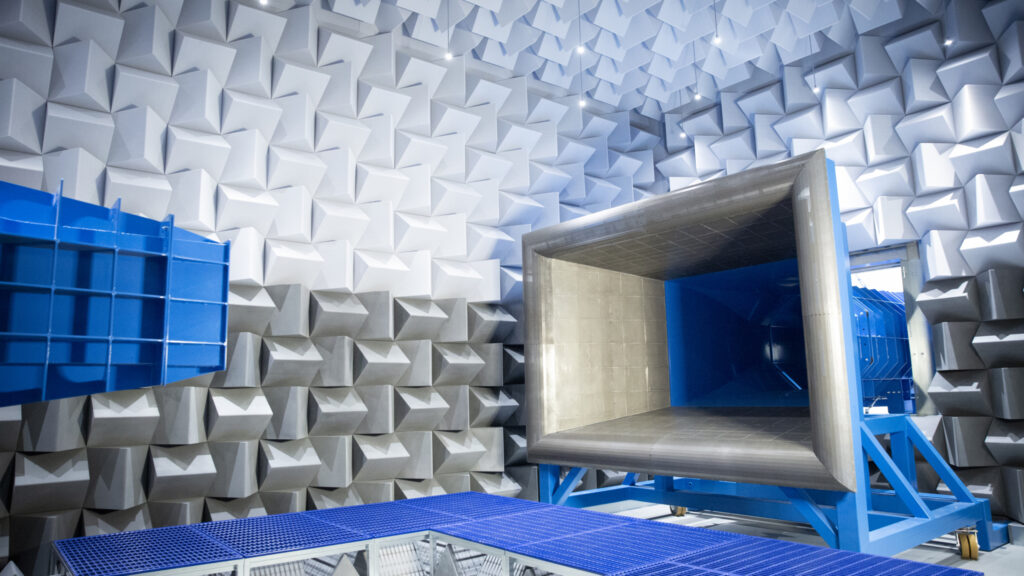

The NLR-AWT is designed to researching the noise production characteristics of various materials and shapes. The tunnel’s unique design features a closed circuit that flows into an ‘anechoic chamber’, which is lined with foam wedges that absorb over 99% of all sound waves above lower bass notes (200 Hz). The facility can accommodate a wide range of model sizes and configurations, from scaled-down versions to full-scale models and partial models. Recent projects have included the development of advanced measurement techniques, noise testing of landing gear and wind turbines in the open jet configuration, and aerodynamic testing such as probe calibrations in the closed test section.

Main features

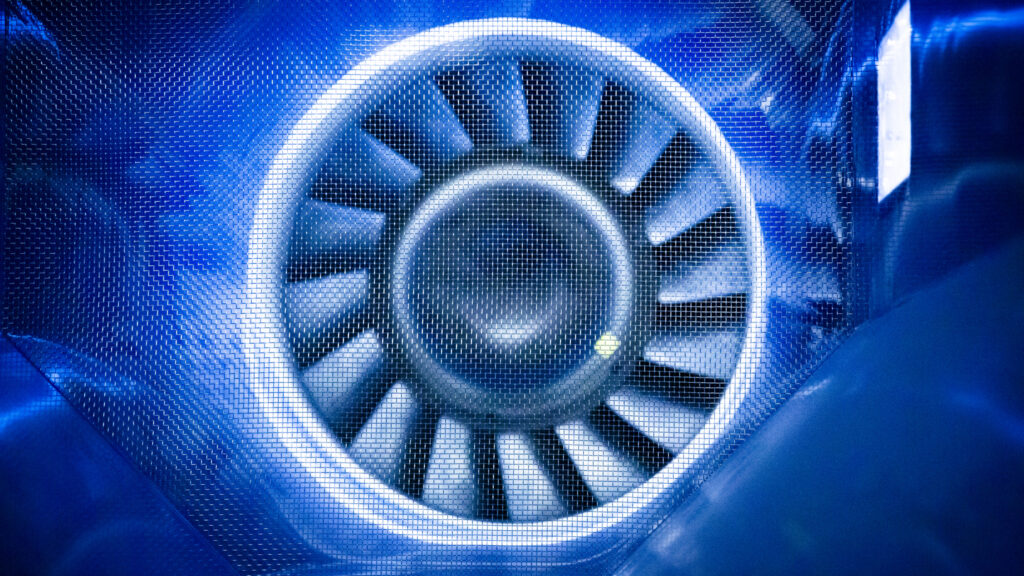

- Closed circuit wind tunnel, powered by two 180kW axial fans, with open jet and closed test sections

- Large anechoic room (9 x 8 x 6 m), completely covered with 0.5 m foam wedges yielding more than 99% absorption at above 200 Hz

- In the frequency range from 200 Hz to 20,000 Hz, the anechoic room is in accordance with ISO 3745:2017

- Wind speeds of up to 100 m/s can be achieved in the open jet configuration and up to 120 m/s in the closed test section 0.8×0.6 m2

- The flow uniformity in the open jet is within 0.1% at the measurement location and turbulence intensity is in the order of 0.1%

- Background Overall Sound Pressure Levels (OASPL) at 1m distance of the nozzle that are ranging from 58dB(A) at Ma=0.1 to 80dB(A) at M=0.2

- Low free stream turbulence level in the closed test section (0.01-0.02% @ 20 m/s, 0.02-0.03 @ 60 m/s and 0.04-0.06% @ 100 m/s)

- Different types of microphones, a microphone array for source location and variable pressure measurement systems

- Various dynamic acquisition systems (up to 200 kHz) for acoustic or other unstable measurements

- Lasers, high speed cameras and double frame cameras for flow visualisation techniques

- A balance for measuring aerodynamic forces

- Hotwire apparatus for measuring turbulence levels